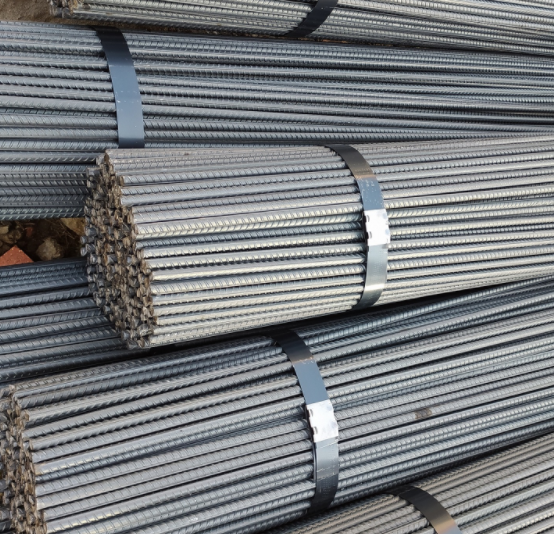

Specs of rebar

| Product name | Steel Rebar |

| Standard | ASTM, AISI, EN, DIN, JIS, GB |

| Grate | HRB400/HRB500/KSD3504 SD400/KSD3504 SD500/ASTM A615,GR40/ASTM GR60/BS4449 B500B/BS4449 B460 Etc. |

| Material | HRB335, HRB400, HRB500, JISG3112-2004 SD390; BS4449-1997 Gr.460B; BS4449:2005 B500B/B500C |

| Specifications | Diameter(6-50mm) 6mm,8mm,10mm,12mm,16mm,20mm,22mm,25mm,28mm,32mm,40mm,50mm Or OEMLength:6m-12m as your required |

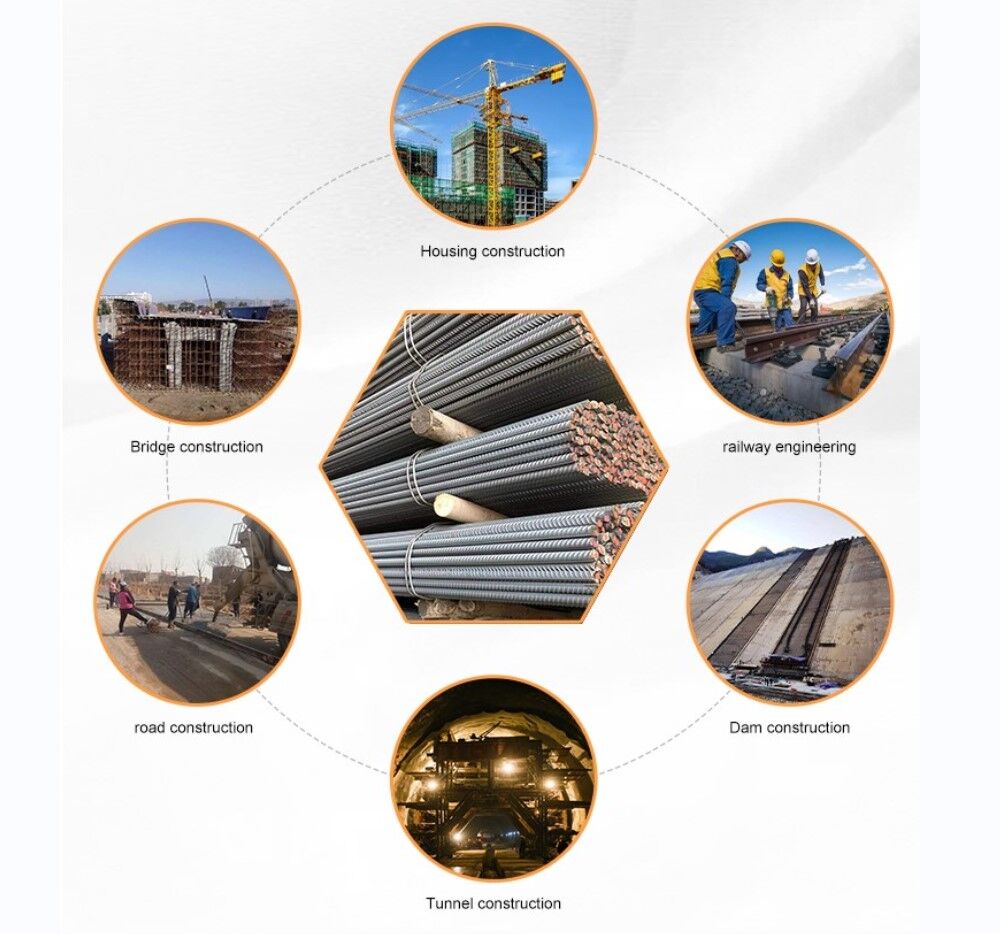

| Application | Rebar is widely used in building, bridge, road and other civil engineering construction. |

| Standard | GB:HRB400 HRB400E HRB500 |

| USA:ASTM A615 GR40,GR60 | |

| UK: BS4449 GR460 | |

| InspectionMethods | Tensile testing |

| (1) Tensile test method: GB/T228.1-2010, JISZ2201, JI SZ2241, ASTMA370, 1497, BS18, etc; | |

| (2) Bending test method: often use standard test methods have GB/T232-88, YB/T5126-2003, JISZ2248, ASTME290, ROCT14019, etc. |

Product Details of rebar

Rebar refers to steel for reinforced concrete and prestressed reinforced concrete, which has a circular cross-section, sometimes square with rounded corners. Including light round steel bars, ribbed steel bars, torsional steel bars.

Reinforced concrete steel bar refers to the straight strip or coiled steel for reinforced concrete reinforcement, its shape is divided into two types: light round steel bar and deformed steel bar, and the delivery status is straight bar and coiled circle.

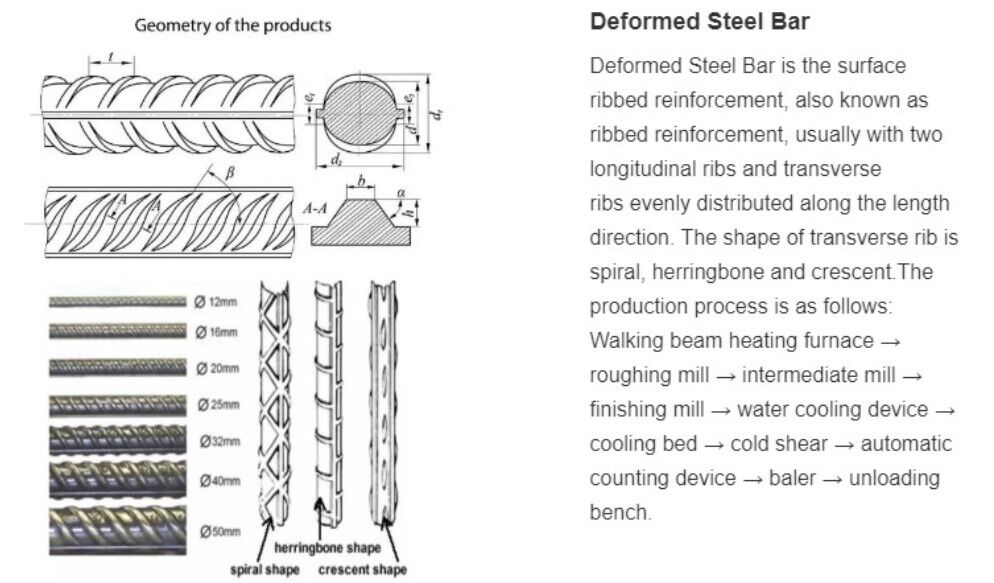

Rebar is a common name for hot-rolled ribbed steel bars. The grade of ordinary hot-rolled steel bar is composed of HRB and the minimum yield point of the grade. H, R, and B are the first letters of the three words: Hotrolled, Ribbed, and Bars respectively. Rebar is a ribbed steel bar on the surface, also known as ribbed steel bar, usually with two longitudinal ribs and transverse ribs evenly distributed along the length. The shape of the transverse ribs is spiral, herringbone, and crescent. It is expressed in millimeters of the nominal diameter.

The nominal diameter of ribbed steel bars is equivalent to the nominal diameter of smooth round steel bars with equal cross-sections. The nominal diameter of the steel bars is 8-50 mm, and the recommended diameters are 8, 12, 16, 20, 25, 32, and 40 mm. Ribbed steel bars mainly bear tensile stress in concrete. Ribbed steel bars have greater bonding capacity with concrete due to the action of ribs, so they can better withstand external forces. Ribbed steel bars are widely used in various building structures, especially large, heavy, light thin-walled and high-rise building structures.

Application

- Rebar is a common name for hot-rolled ribbed steel bars. The grade of ordinary hot-rolled steel bar is composed of HRB and the minimum yield point of the grade. H, R, and B are the first letters of the three words: Hotrolled, Ribbed, and Bars respectively. Rebar is a ribbed steel bar on the surface, also known as ribbed steel bar, usually with two longitudinal ribs and transverse ribs evenly distributed along the length. The shape of the transverse ribs is spiral, herringbone, and crescent. It is expressed in millimeters of the nominal diameter.

- The nominal diameter of ribbed steel bars is equivalent to the nominal diameter of smooth round steel bars with equal cross-sections. The nominal diameter of the steel bars is 8-50 mm, and the recommended diameters are 8, 12, 16, 20, 25, 32, and 40 mm. Ribbed steel bars mainly bear tensile stress in concrete. Ribbed steel bars have greater bonding capacity with concrete due to the action of ribs, so they can better withstand external forces. Ribbed steel bars are widely used in various building structures, especially large, heavy, light thin-walled and high-rise building structures.

Packaging

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

FAQ

| Q1: What is the MOQ for Rebar? | 1 tons for each size |

| Q2: What is your payment term? | We operate on T/T (Telegraphic Transfer) first. Deposit & balance ratio: Flexible negotiation (typically 30% deposit, 70% before shipment). Full SWIFT/BIC codes and proforma invoice (PI) provided within 24hrs post-order confirmation. |

| Q3: How is quality compliance guaranteed? | Our 4-Stage Verification System: ① Mill Test Certificates (MTC) with traceable batch numbers; ② Dimensional/spectral analysis in ISO 9001 & university-partnered labs; ③ Optional third-party inspections (SGS/BV at cost); ④ Real-time production inspection records (photos/videos shared pre-shipment). |

| Q4: What are your production lead times? | Standard stock: 7 working days after deposit clearance. Custom processing: 15-25 days (Technical review within 48hrs). |

| Q5: What custom processing capabilities do you offer? | Key services at Wuxi & Wuhan Centers: Cutting: Laser (±0.2mm), Waterjet, Slitting Surfacing: Passivation, Electropolishing, Anodizing CNC Machining: ±0.05mm tolerance, 0.1° angular accuracy MOQ: 2MT for custom orders; DFM analysis provided. |

| Q6: How do you manage global logistics? | Trade Terms: EXW, FOB, CIF, DAP, DDP Key Routes: Asia/Oceania: 7-12 days via Shanghai/Shenzhen ports Europe/N.America: 20-35 days Export docs: CO, FORM E, CE/PED (*on demand) |

| Q7: What is your defective goods policy? | Claim window: 7 calendar days post-delivery. Process: ① Joint video audit within 24hrs; ② Identify the cause of the problem; ③ Compensation for proven non-conformance |