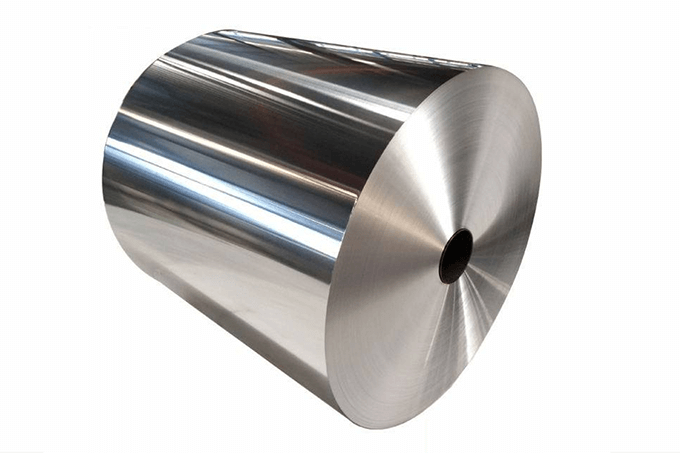

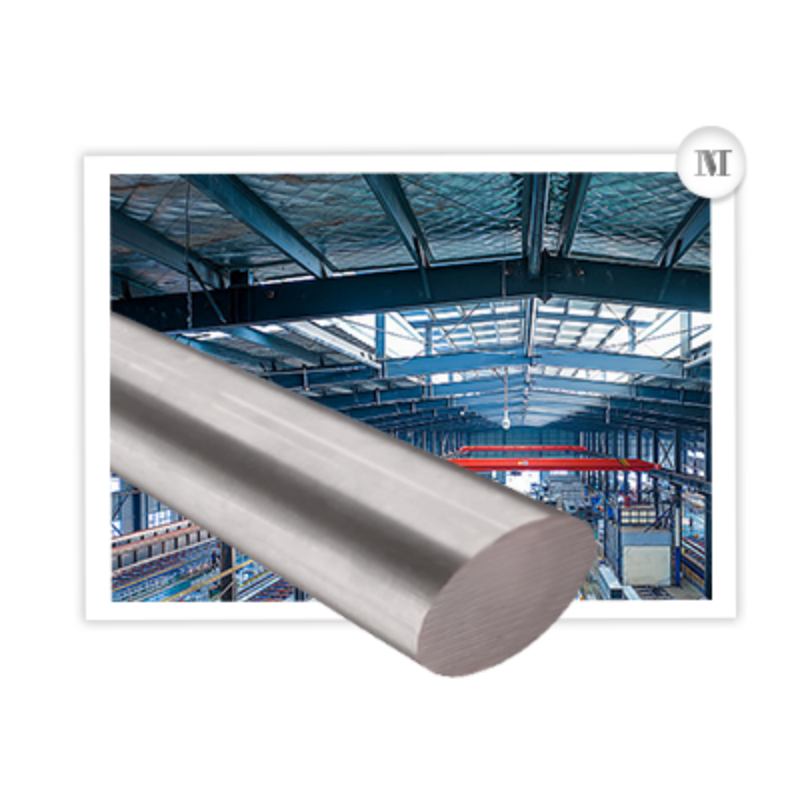

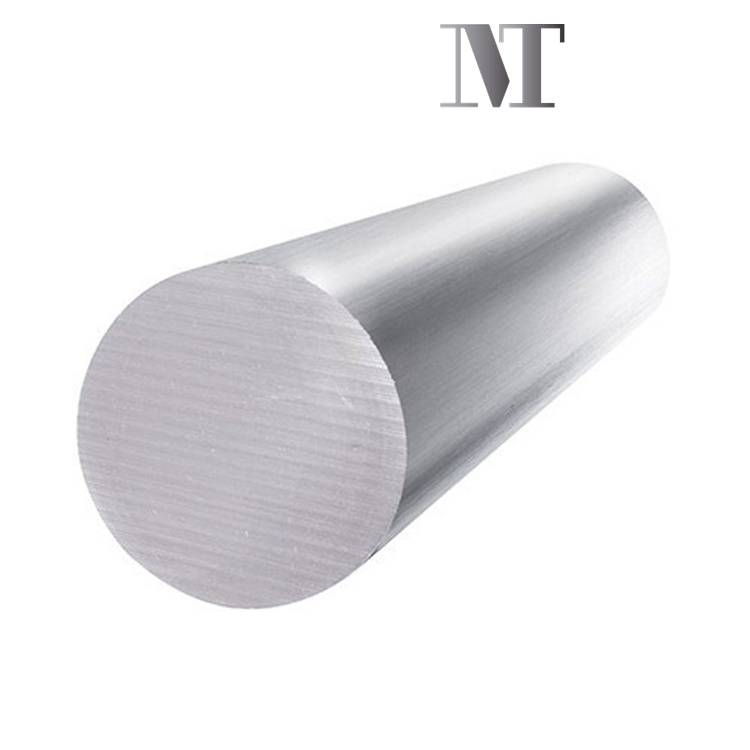

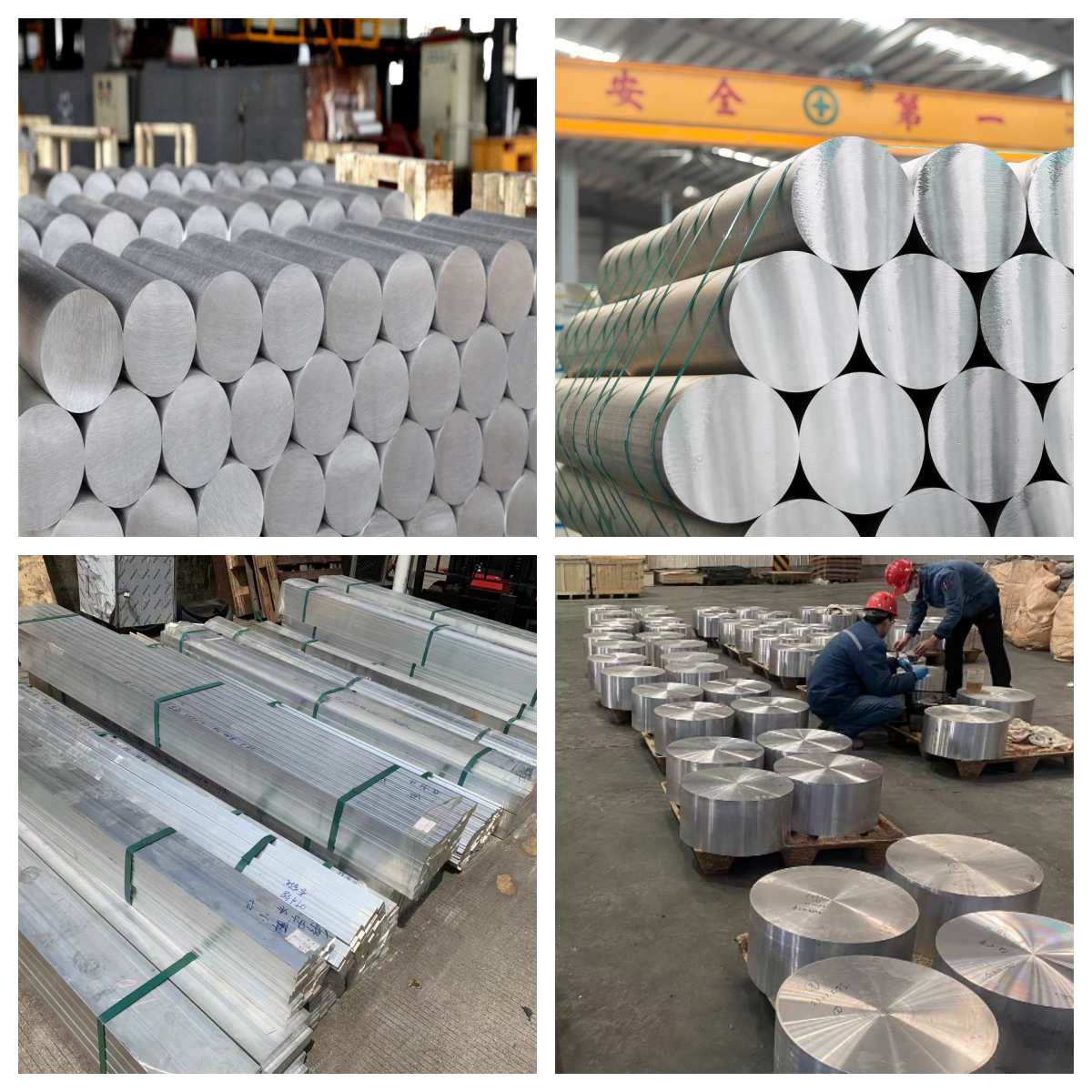

Specs of aluminum rod

Products Description

According to the different metal elements contained in aluminum rods, aluminum rods can be roughly divided into 8 categories, that is, they can be divided into 9 series:

1)The 1000 series aluminum rods represent the 1050, 1060, and 1100 series. In all series, the 1000 series belongs to the series with the most aluminum content. The purity can reach more than 99.00%. Because it does not contain other technical elements, the production process is relatively simple and the price is relatively cheap. It is currently the most commonly used series in conventional industries. Most of the products circulating in the market are 1050 and 1060 series.

2) 2000 series aluminum rods represent 2A16 (LY16) and 2A02 (LY6). The 2000 series aluminum rods are characterized by high hardness, with the highest content of copper, which is about 3-5%. The 2000 series aluminum rods belong to aviation aluminum materials, which are not often used in conventional industries.

3) 3000 series aluminum rods mainly represent 3003 and 3A21. The production technology of 3000 series aluminum rods in my country is relatively excellent. 3000 series aluminum rods are made of manganese as the main component. The content is between 1.0-1.5, which is a series with better anti-rust function.

4) 4000 series aluminum rods The representative is 4A01 4000 series aluminum rods belong to the series with higher silicon content. Usually the silicon content is between 4.5-6.0%. It belongs to construction materials, mechanical parts, forging materials, welding materials; low melting point, good corrosion resistance, product description: heat-resistant and wear-resistant

5) The 5000 series aluminum rods represent the 5052, 5005, 5083, and 5A05 series. The 5000 series aluminum rods belong to the more commonly used alloy aluminum rod series, the main element is magnesium, and the magnesium content is between 3-5%. It can also be called aluminum-magnesium alloy. The main features are low density, high tensile strength and high elongation. In the same area, the weight of aluminum-magnesium alloy is lower than that of other series, and it is also widely used in conventional industries. In my country, the 5000 series aluminum rod is one of the more mature aluminum rod series.

6) 6000 series aluminum rods represent 6061 and 6063 mainly containing magnesium and silicon. Therefore, the advantages of 4000 series and 5000 series are concentrated. 6061 is a cold-treated aluminum forging product, suitable for applications with high requirements for corrosion resistance and oxidation. . Good workability, easy coating and good processability.

7) 7000 series aluminum rods represent 7075 and mainly contain zinc. It also belongs to the aerospace series. It is an aluminum-magnesium-zinc-copper alloy, a heat-treatable alloy, and a super-hard aluminum alloy with good wear resistance. Basically relying on imports, my country’s production technology needs to be improved.

8) 8000 series aluminum rods The more commonly used 8011 belongs to other series, and most of the applications are aluminum foil, which is not commonly used in the production of aluminum rods.

Application

1. Aluminum rods are widely used in decoration, packaging, construction, transportation, electronics, aviation, aerospace, weapons and other industries.

2. Aluminum rods for transportation are used as materials for the body structure of automobiles, subway vehicles, railway passenger cars, high-speed passenger cars, car doors and windows, shelves, automobile engine parts, air conditioners, radiators, body panels, hubs and naval materials .

3. Aluminum materials for printing are mainly used to make various PS plates. Aluminum-based PS plates are a new type of material in the printing industry for automated plate making and printing.

4. Aluminum for architectural decoration. Aluminum alloy is widely used in building frames, doors and windows, suspended ceilings, decorative surfaces, etc.

Packaging

FAQ

| Q1: What is the MOQ for aluminum rods? | 8tons for customized size; 500kgs for regular size |

| Q2: What is your payment term? | We operate on T/T (Telegraphic Transfer) first. Deposit & balance ratio: Flexible negotiation (typically 30% deposit, 70% before shipment). Full SWIFT/BIC codes and proforma invoice (PI) provided within 24hrs post-order confirmation. |

| Q3: How is quality compliance guaranteed? | Our 4-Stage Verification System: ① Mill Test Certificates (MTC) with traceable batch numbers; ② Dimensional/spectral analysis in ISO 9001 & university-partnered labs; ③ Optional third-party inspections (SGS/BV at cost); ④ Real-time production inspection records (photos/videos shared pre-shipment). |

| Q4: What are your production lead times? | Standard stock: 7 working days after deposit clearance. Custom processing: 15-25 days (Technical review within 48hrs). |

| Q5: What custom processing capabilities do you offer? | Key services at Wuxi & Wuhan Centers: Cutting: Laser (±0.2mm), Waterjet, Slitting Surfacing: Passivation, Electropolishing, Anodizing CNC Machining: ±0.05mm tolerance, 0.1° angular accuracy MOQ: 2MT for custom orders; DFM analysis provided. |

| Q6: How do you manage global logistics? | Trade Terms: EXW, FOB, CIF, DAP, DDP Key Routes: Asia/Oceania: 7-12 days via Shanghai/Shenzhen ports Europe/N.America: 20-35 days Export docs: CO, FORM E, CE/PED (*on demand) |

| Q7: What is your defective goods policy? | Claim window: 7 calendar days post-delivery. Process: ① Joint video audit within 24hrs; ② Identify the cause of the problem; ③ Compensation for proven non-conformance |