Video of aluminum coil

Specs of aluminum coil

Products Description

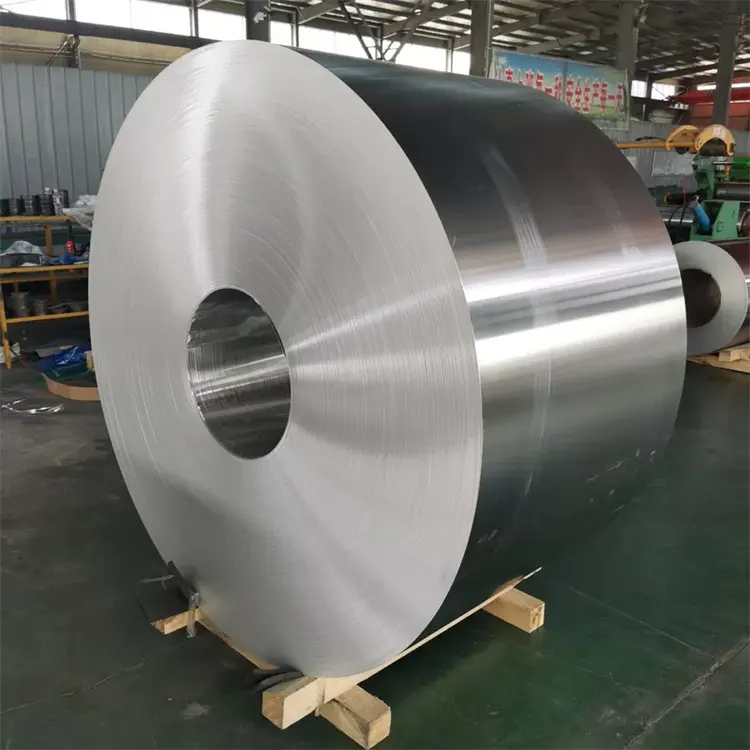

Available in alloys in the 1000 to 8000 series range, we stock a full range of aluminum coils to service a wide range ofindustries, including automotive, pharmaceutical, electrical, and food service. It is important to note that choosing the rightalloy for the aluminum coil is directly dependent on the specific use case.

Production technology of aluminum coil: aluminum into melting furnace, melting with gas combustion, grilled slag in addition to waste, configuration, guide the furnace to the holding furnace, aluminum alloy, after die casting mouth water, rolling roll roll, rolling cold rolled coil, annealing, cross cut to required size, engraving, ruffled, reinforcement according to the drawing, welding, grinding, painting, inspection, stick protective film, bag air cushion film, packaging.

Product Details of aluminum coil

Specification

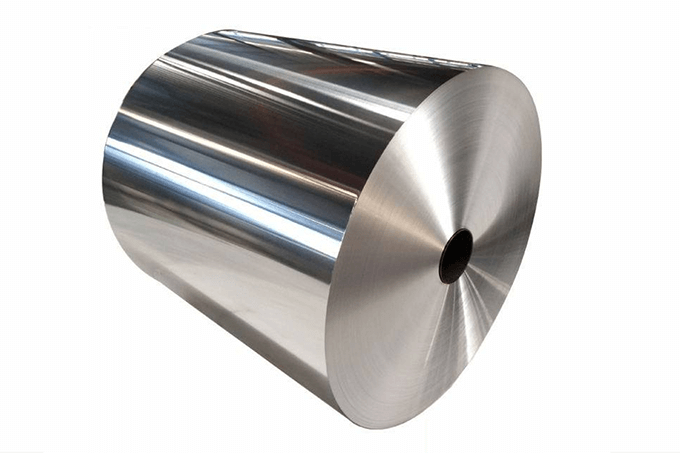

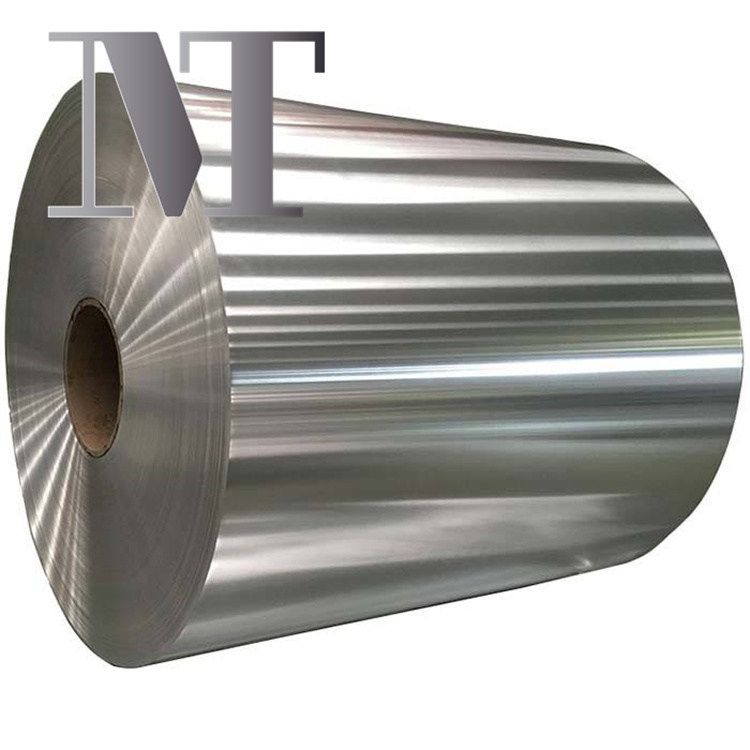

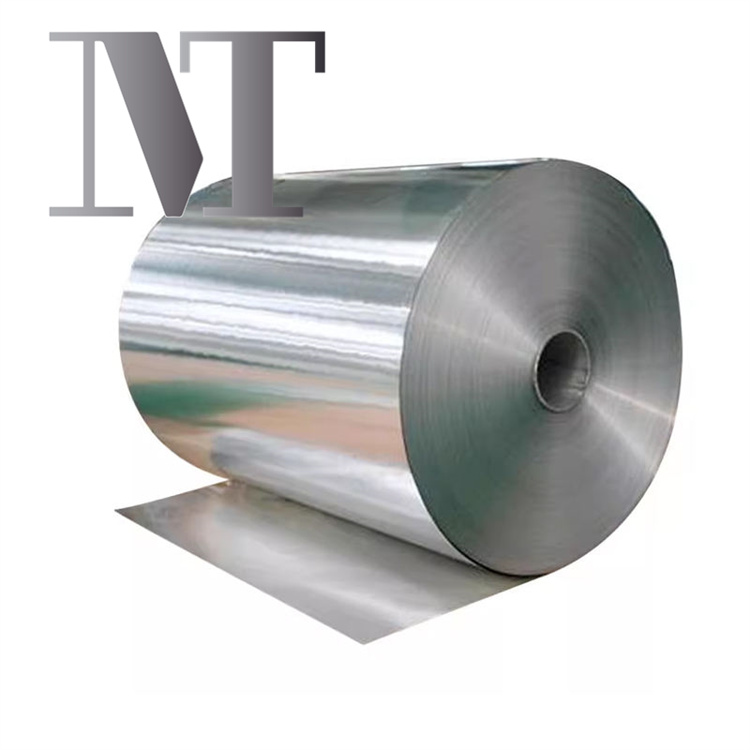

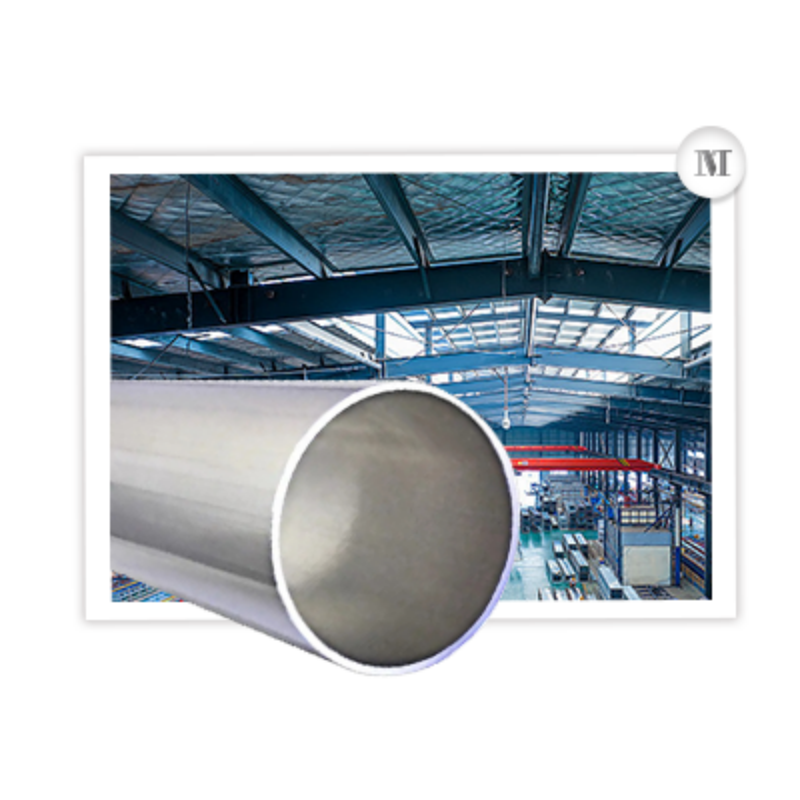

Aluminum coil. Aluminum coil is a metal product used for flying shear after calendering and bending processing by casting and rolling machine. Produced in the form of continuous coil steel, with inside and outside diameters. Common alloy coils are used in a wide variety of applications.Buy any aluminum coils, it is vital that you understand the specific strain the material will face during use. Attributes to note include:

• Tensile strength

• wettability

• solderability

• Formability

• Corrosion resistance

Application

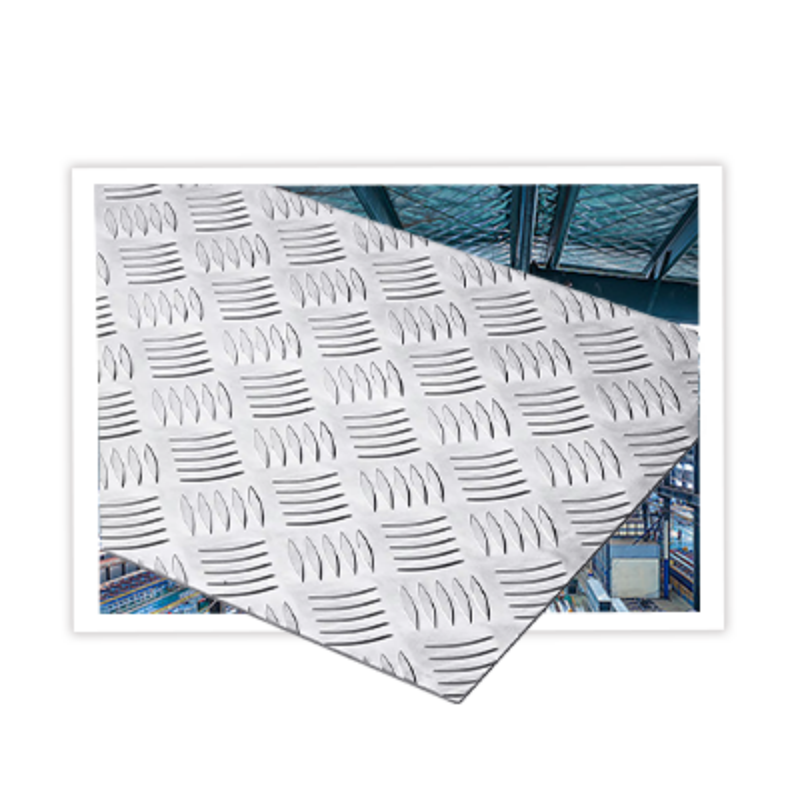

Aluminum steel coil is a type of coil material made of a mixture of aluminum and steel, which has the lightweight and corrosion resistance of aluminum, as well as the strength and wear resistance of steel. Aluminum steel coils are widely used in fields such as architecture, automobiles, and electrical appliances, such as building roofs, walls, doors and windows, car bodies, and electrical enclosures. The production process of aluminum steel coils includes steps such as mixing, rolling, cutting, and surface treatment of aluminum and steel. The advantages of aluminum steel coils include lightweight, corrosion resistance, high strength, and ease of processing.

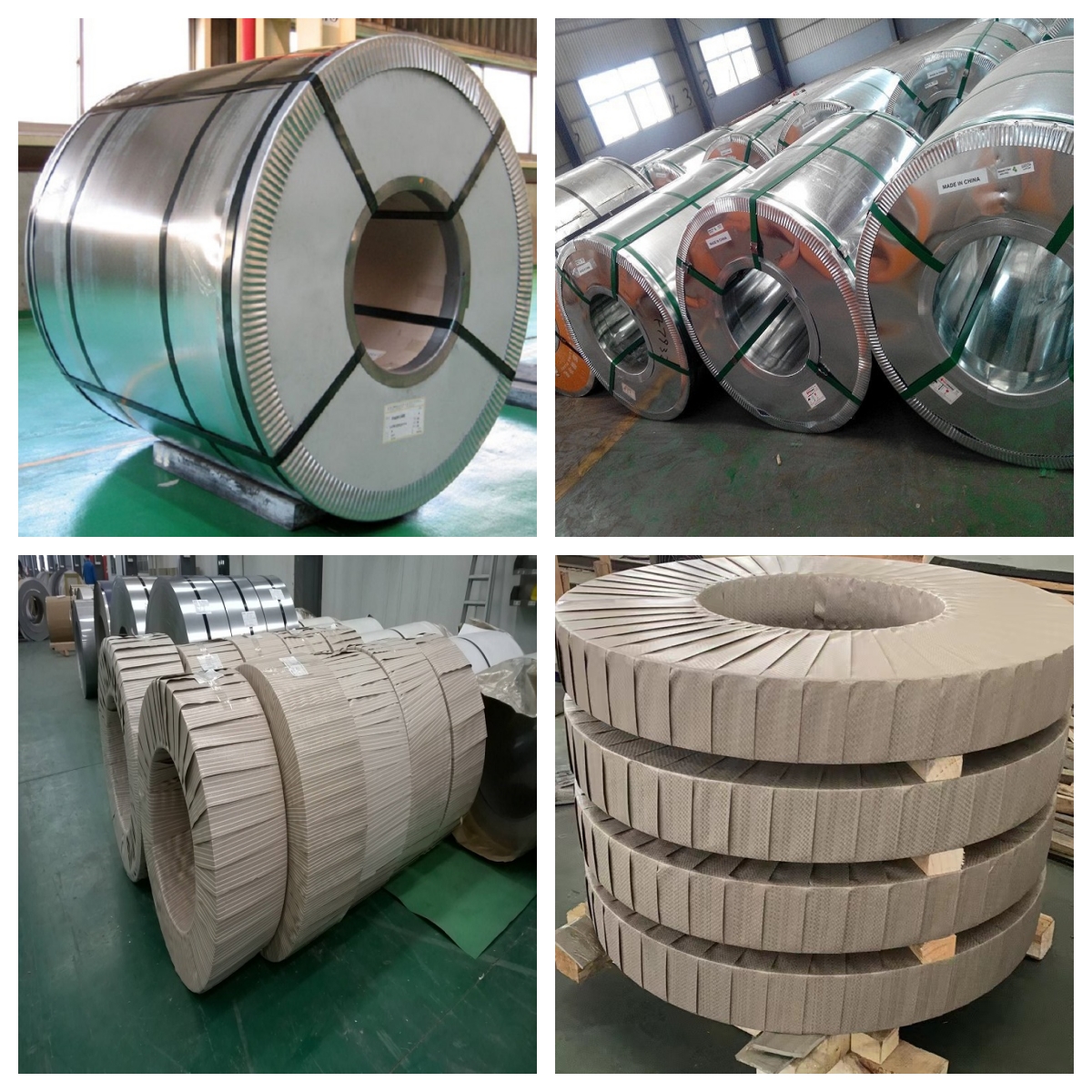

Packaging

FAQ

| Q1: What is the MOQ for aluminum coils? | 8 tons for customized size; 500kgs for regular size |

| Q2: What is your payment term? | We operate on T/T (Telegraphic Transfer) first. Deposit & balance ratio: Flexible negotiation (typically 30% deposit, 70% before shipment). Full SWIFT/BIC codes and proforma invoice (PI) provided within 24hrs post-order confirmation. |

| Q3: How is quality compliance guaranteed? | Our 4-Stage Verification System: ① Mill Test Certificates (MTC) with traceable batch numbers; ② Dimensional/spectral analysis in ISO 9001 & university-partnered labs; ③ Optional third-party inspections (SGS/BV at cost); ④ Real-time production inspection records (photos/videos shared pre-shipment). |

| Q4: What are your production lead times? | Standard stock: 7 working days after deposit clearance. Custom processing: 15-25 days (Technical review within 48hrs). |

| Q5: What custom processing capabilities do you offer? | Key services at Wuxi & Wuhan Centers: Cutting: Laser (±0.2mm), Waterjet, Slitting Surfacing: Passivation, Electropolishing, Anodizing CNC Machining: ±0.05mm tolerance, 0.1° angular accuracy MOQ: 2MT for custom orders; DFM analysis provided. |

| Q6: How do you manage global logistics? | Trade Terms: EXW, FOB, CIF, DAP, DDP Key Routes: Asia/Oceania: 7-12 days via Shanghai/Shenzhen ports Europe/N.America: 20-35 days Export docs: CO, FORM E, CE/PED (*on demand) |

| Q7: What is your defective goods policy? | Claim window: 7 calendar days post-delivery. Process: ① Joint video audit within 24hrs; ② Identify the cause of the problem; ③ Compensation for proven non-conformance |