Video of carbon steel rod

Specs of carbon steel rod

|

Products Name

|

Round bar

|

|

Standard

|

JIS ASTM GB

|

|

Place of Origin

|

Shandong China

|

|

Processing range

|

OD: 12.7-3000mm, WT:0.5-50mm

|

|

Brand Name

|

Angang

|

|

Welded method

|

TIG OR PLASMA + TIG

|

|

Processing ability

|

Pickling, X-Ray flaw detector, Hydrostatic testing, Annealing treatment

|

|

Tolerance

|

±1%

|

|

Processing Service

|

Bending, WELDING, Decoiling, PUNCHING, Cutting,

|

|

Material

|

JIS G4051-2005

|

|

Length

|

6000mm 5800mm

|

|

Surface finish

|

smooth

|

|

Shape

|

Round Pipe Tube

|

|

Usage

|

Industry,Water Pipeline,Heat Exchanger, etc

|

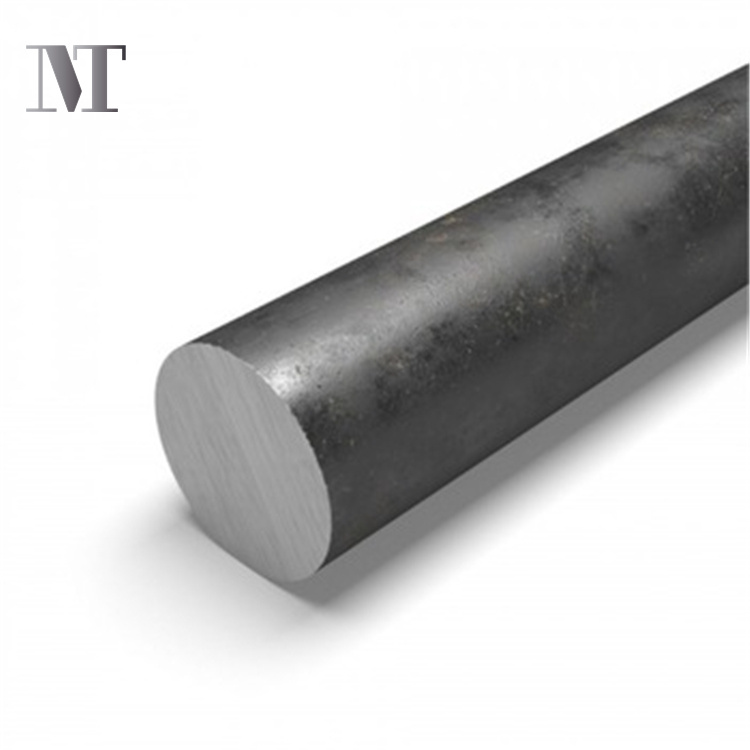

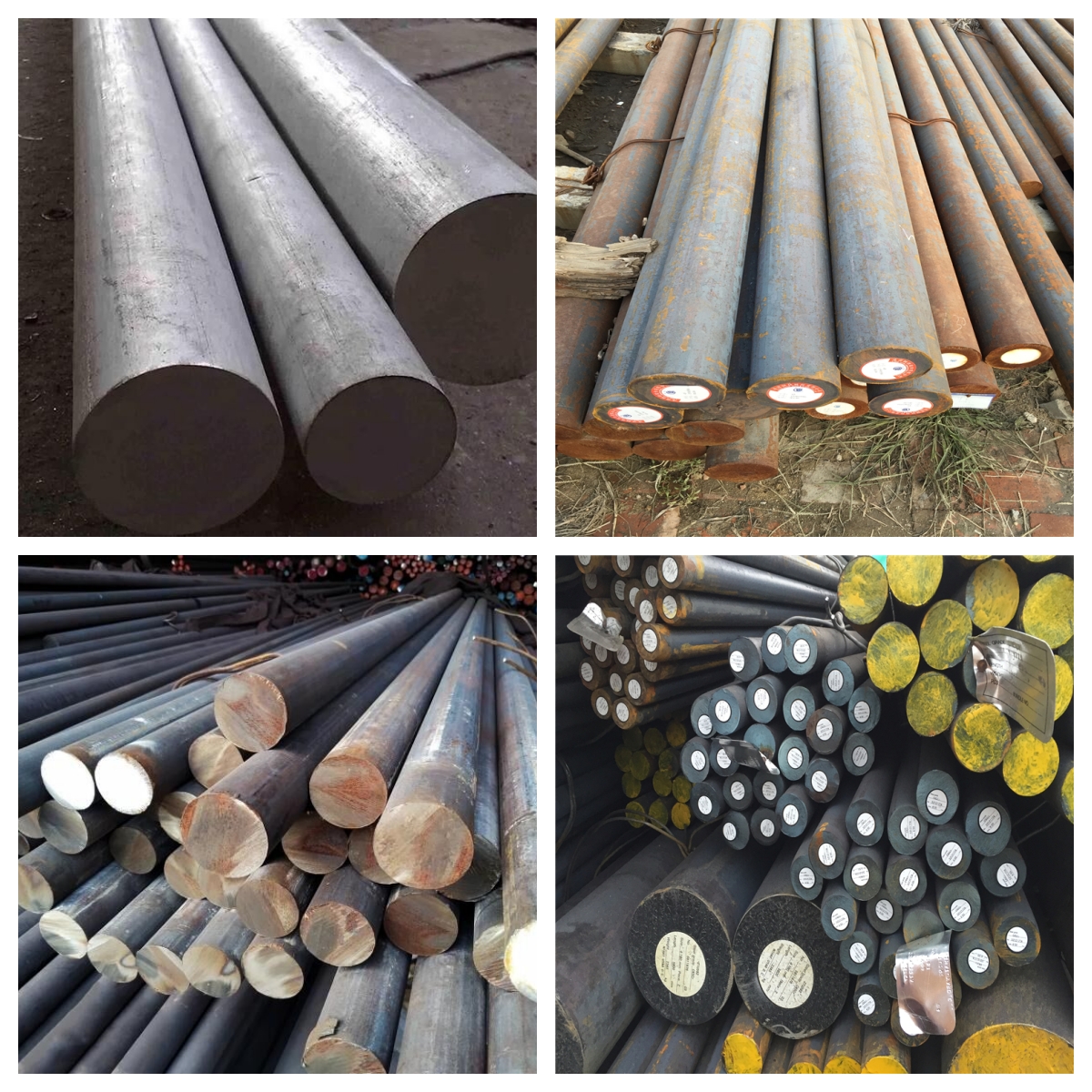

Product Details of carbon steel rod

- Round steel refers to long solid steel with circular section. Its specification is expressed in diameter.

Round steel is divided into hot rolling, forging and cold drawing. The specification of hot rolled round steel is 5.5-250mm. Among them, 5.5-25mm small round steel is mostly supplied in bundles of straight bars, which is often used as reinforcement, bolts and various mechanical parts; Round steel larger than 25mm is mainly used for manufacturing mechanical parts, pipe blank of seamless steel pipe, etc. - Difference between round steel and other reinforcement:

1. The appearance of round steel is different. The appearance of round steel is smooth and round, without lines and ribs, and the appearance of other reinforcement surfaces is engraved or ribbed.

2. The composition is different. Round steel belongs to ordinary low carbon steel, and other reinforcement is mostly alloy steel.

3. The strength is different. The strength of round steel is low and that of other steels is high, but the plasticity of round steel is stronger than that of other rebars.

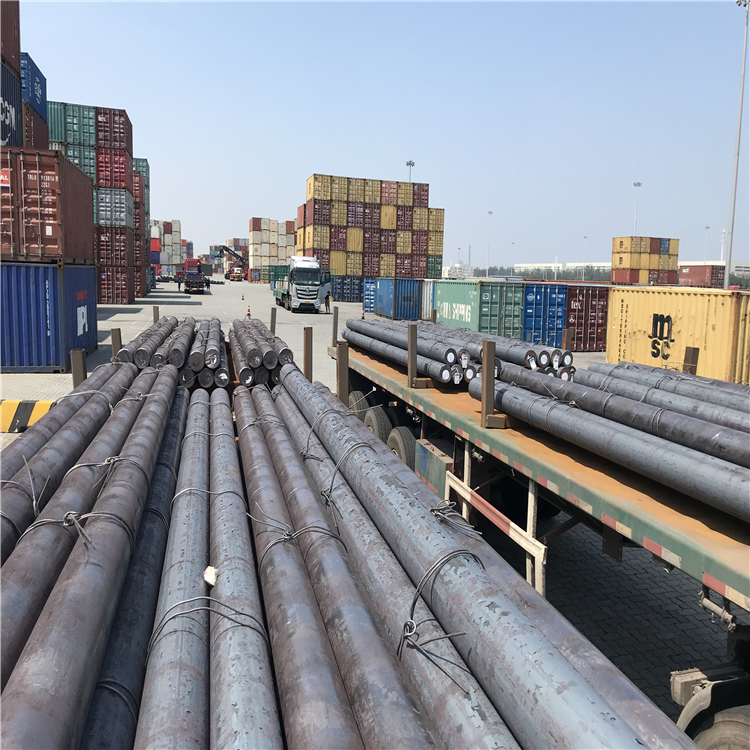

Packaging

FAQ

| Q1: What is the MOQ for carbon steel rods? | 5 tons for each size |

| Q2: What is your payment term? | We operate on T/T (Telegraphic Transfer) first. Deposit & balance ratio: Flexible negotiation (typically 30% deposit, 70% before shipment). Full SWIFT/BIC codes and proforma invoice (PI) provided within 24hrs post-order confirmation. |

| Q3: How is quality compliance guaranteed? | Our 4-Stage Verification System: ① Mill Test Certificates (MTC) with traceable batch numbers; ② Dimensional/spectral analysis in ISO 9001 & university-partnered labs; ③ Optional third-party inspections (SGS/BV at cost); ④ Real-time production inspection records (photos/videos shared pre-shipment). |

| Q4: What are your production lead times? | Standard stock: 7 working days after deposit clearance. Custom processing: 15-25 days (Technical review within 48hrs). |

| Q5: What custom processing capabilities do you offer? | Key services at Wuxi & Wuhan Centers: Cutting: Laser (±0.2mm), Waterjet, Slitting Surfacing: Passivation, Electropolishing, Anodizing CNC Machining: ±0.05mm tolerance, 0.1° angular accuracy MOQ: 2MT for custom orders; DFM analysis provided. |

| Q6: How do you manage global logistics? | Trade Terms: EXW, FOB, CIF, DAP, DDP Key Routes: Asia/Oceania: 7-12 days via Shanghai/Shenzhen ports Europe/N.America: 20-35 days Export docs: CO, FORM E, CE/PED (*on demand) |

| Q7: What is your defective goods policy? | Claim window: 7 calendar days post-delivery. Process: ① Joint video audit within 24hrs; ② Identify the cause of the problem; ③ Compensation for proven non-conformance |