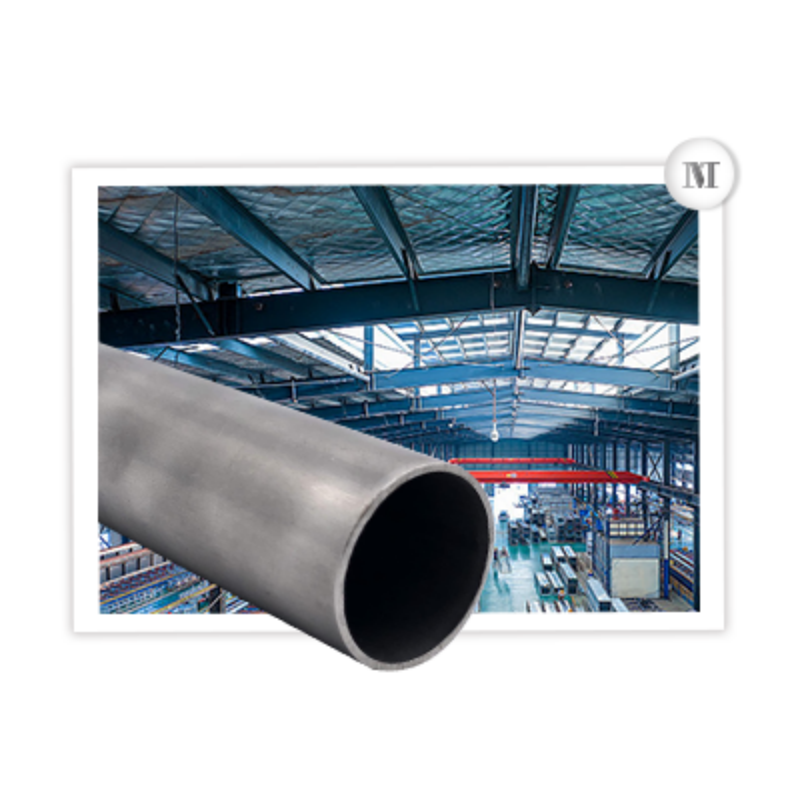

Video of steel pipe

Specs of steel pipe

|

Product name

|

Carbon Steel Seamless Pipe

|

|

ASTM

|

A53,A283,A106-A,A179,A214C,A192,A226,A315,A106,A178,

|

|

GB

|

16Mn20Cr,40Cr,35CrMo,45CrMo,10CrMo910,15MnV,09Mn2v,06A1NbCuN,16Mo,12CrMo,15CrMoG,12Cr1MoVG,Cr5Mo,1Gr13,2Cr13,1Cr17

|

|

JIS

|

G3452 G3457 G3456 G3461 G3454 G3455

|

|

DIN

|

DIN1626 DIN17175 DIN1629/4 DIN1629/3

|

|

Dimensions

|

OD10mm-930mm*WT1-180mm or customized

|

|

Length:

|

6-12M or as required

|

|

Standard:

|

ASTM,AISI,JIS,GB, DIN,EN

|

|

Surface treatment

|

Black/Peeling/Polishing/Machined

|

|

Technique

|

Cold/Hot rolled, Cold-Drawn, or Hot Forged

|

|

Heat Treatment

|

Annealed; Quenched; Tempered

|

|

price terms

|

FOB,CRF,CIF,EXW all acceptable

|

|

Delivery Detail

|

inventory About 3-5; custom-made 10-15;rding to order’s quantity.

|

|

Loading port

|

any port in China

|

|

Packing

|

standard export packing (inside:water proof paper,outside:steel covered with strips and pallets)

|

Product Details of steel pipe

Steel pipes are long, hollow tubes with a variety of uses. They are produced using two different methods, resulting in either welded or seamless pipes. In both methods, crude steel is first cast into an initial shape that is easier to work with. The steel is then stretched into a seamless tube or its edges are pressed together and sealed with a weld to form a pipe.

Application

1. For pipelines. Water, gas pipes, steam pipes, and oil and gas trunk lines.

2. Tubes for thermal equipment. Superheating pipes, high temperature and high-pressure boiler pipes for locomotive boilers.

3. For the machinery industry. Aviation structural tubes, automobile axle tubes, tractor structural tubes, etc.

Packaging

FAQ

| Q1: What is the MOQ for steel pipe? | 5 tons for each size |

| Q2: What is your payment term? | We operate on T/T (Telegraphic Transfer) first. Deposit & balance ratio: Flexible negotiation (typically 30% deposit, 70% before shipment). Full SWIFT/BIC codes and proforma invoice (PI) provided within 24hrs post-order confirmation. |

| Q3: How is quality compliance guaranteed? | Our 4-Stage Verification System: ① Mill Test Certificates (MTC) with traceable batch numbers; ② Dimensional/spectral analysis in ISO 9001 & university-partnered labs; ③ Optional third-party inspections (SGS/BV at cost); ④ Real-time production inspection records (photos/videos shared pre-shipment). |

| Q4: What are your production lead times? | Standard stock: 7 working days after deposit clearance. Custom processing: 15-25 days (Technical review within 48hrs). |

| Q5: What custom processing capabilities do you offer? | Key services at Wuxi & Wuhan Centers: Cutting: Laser (±0.2mm), Waterjet, Slitting Surfacing: Passivation, Electropolishing, Anodizing CNC Machining: ±0.05mm tolerance, 0.1° angular accuracy MOQ: 2MT for custom orders; DFM analysis provided. |

| Q6: How do you manage global logistics? | Trade Terms: EXW, FOB, CIF, DAP, DDP Key Routes: Asia/Oceania: 7-12 days via Shanghai/Shenzhen ports Europe/N.America: 20-35 days Export docs: CO, FORM E, CE/PED (*on demand) |

| Q7: What is your defective goods policy? | Claim window: 7 calendar days post-delivery. Process: ① Joint video audit within 24hrs; ② Identify the cause of the problem; ③ Compensation for proven non-conformance |