Video of galvanized steel sheet

Specs of galvanized steel sheet

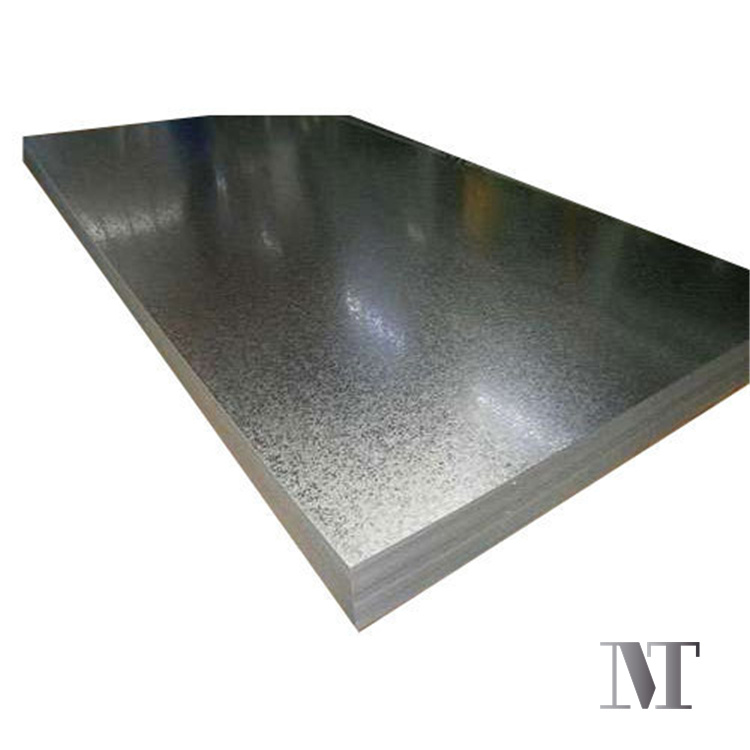

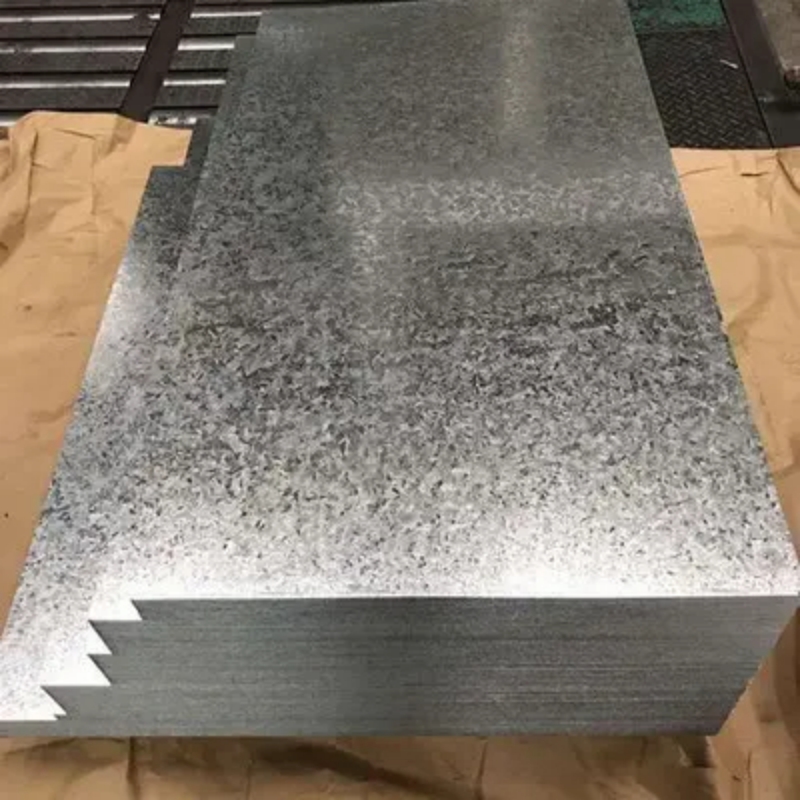

Products Description

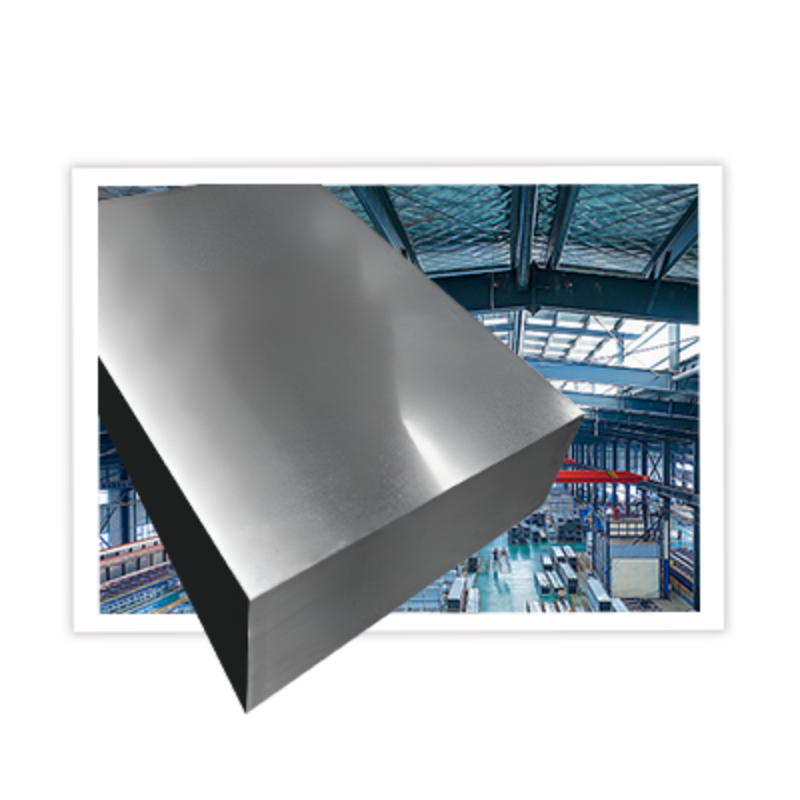

| item | Galvanized Steel Sheet/Plate |

| Place of Origin | Tianjin, China |

| Brand Name | ToMetal |

| Thickness | 0.12-10mm |

| Width | 900mm, 1000mm, 1220mm, 1250mm or according to customer’s requirements |

| Grade | SPCC, DX51D, DX53D, etc. |

| Surface Treatment | Hot Dipped Galvanized |

| Tolerance | ±1% |

| Invoicing | by actual weight |

| Delivery Time | within 7 days |

| MOQ | 1 Tons |

| Payment terms | T/T (30%DEPOSIT, BALANCE PAYMENT BEFORE LOADING) |

| Package | Seaworthy Standard Package |

| Secondary Or Not | Not-secondary |

| Sample | Freely |

| Inspection | Thirdy Inspection Party |

| Advantage | 24 hours service, fast Delivery |

Product Details of galvanized steel sheet

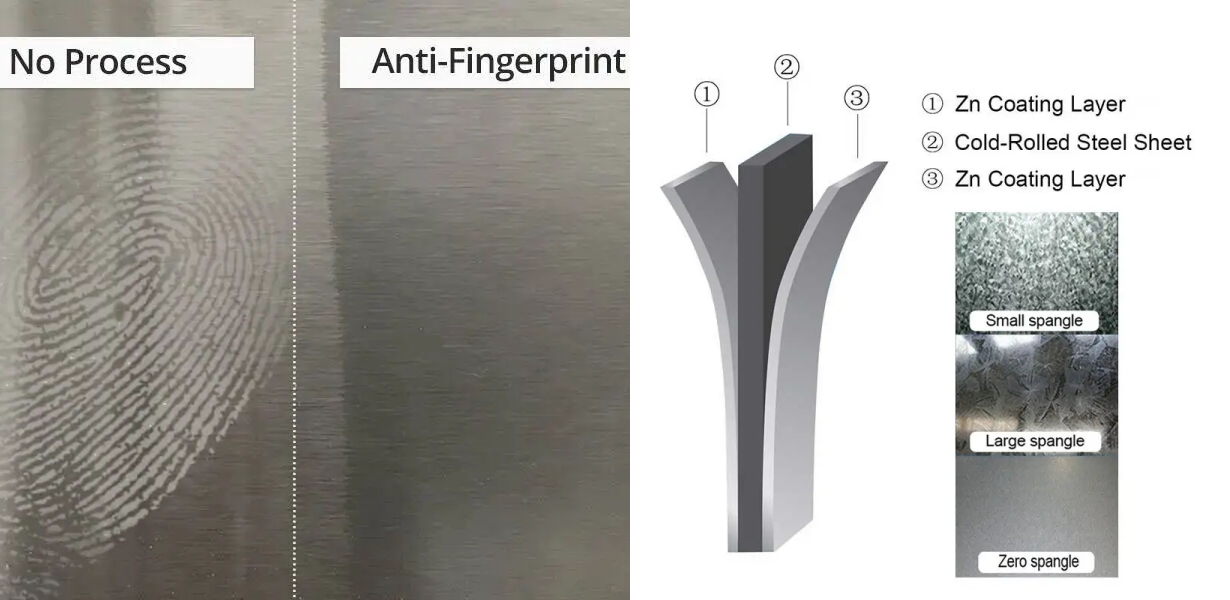

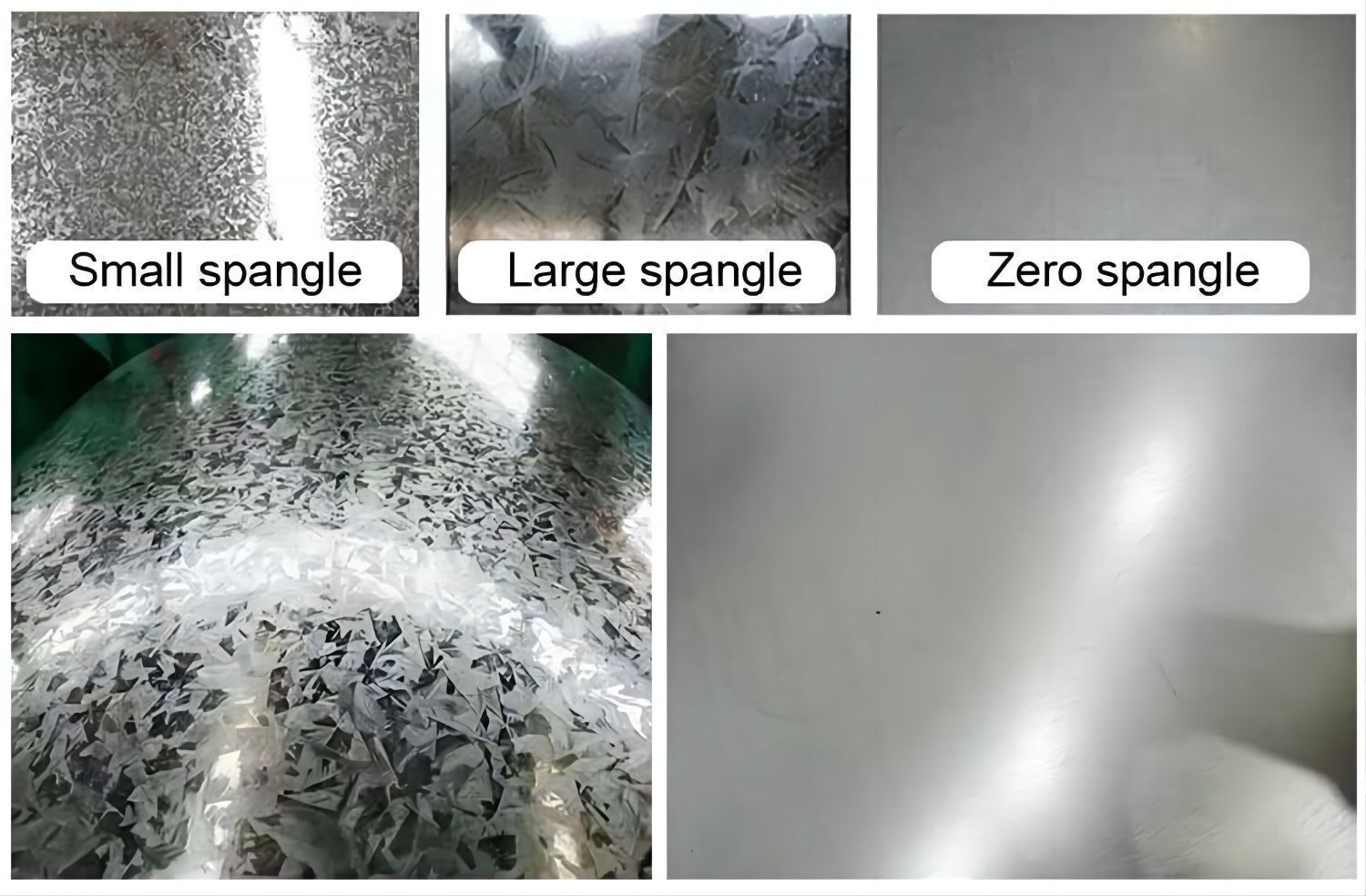

Key Specifications/ Special Features:

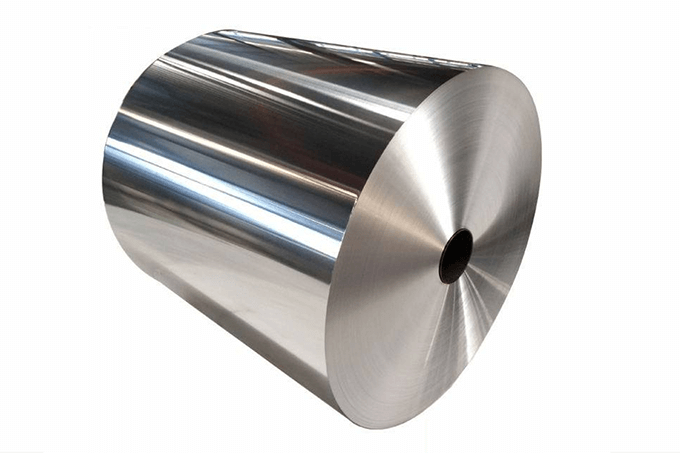

Galvanized coils, the thin steel plate is immersed in the molten zinc bath to make the surface of the zinc thin steel plate adhered.

It is mainly produced by continuous galvanizing process, that is, the coiled steel sheet is continuously immersed in a galvanizing tank with molten zinc to make galvanized steel sheet; alloyed galvanized steel sheet.

This kind of steel plate is also manufactured by hot dipping method, but immediately after leaving the tank, it is heated to about 500°C to form an alloy film of zinc and iron. This galvanized coil has good paint adhesion and weldability.

Packaging

FAQ

| Q1: What is the MOQ for galvanized steel sheet? | Gerellay, 4 tons, if the size is regular, 1 ton is enough |

| Q2: What is your payment term? | We operate on T/T (Telegraphic Transfer) first. Deposit & balance ratio: Flexible negotiation (typically 30% deposit, 70% before shipment). Full SWIFT/BIC codes and proforma invoice (PI) provided within 24hrs post-order confirmation. |

| Q3: How is quality compliance guaranteed? | Our 4-Stage Verification System: ① Mill Test Certificates (MTC) with traceable batch numbers; ② Dimensional/spectral analysis in ISO 9001 & university-partnered labs; ③ Optional third-party inspections (SGS/BV at cost); ④ Real-time production inspection records (photos/videos shared pre-shipment). |

| Q4: What are your production lead times? | Standard stock: 7 working days after deposit clearance. Custom processing: 15-25 days (Technical review within 48hrs). |

| Q5: What custom processing capabilities do you offer? | Key services at Wuxi & Wuhan Centers: Cutting: Laser (±0.2mm), Waterjet, Slitting Surfacing: Passivation, Electropolishing, Anodizing CNC Machining: ±0.05mm tolerance, 0.1° angular accuracy MOQ: 2MT for custom orders; DFM analysis provided. |

| Q6: How do you manage global logistics? | Trade Terms: EXW, FOB, CIF, DAP, DDP Key Routes: Asia/Oceania: 7-12 days via Shanghai/Shenzhen ports Europe/N.America: 20-35 days Export docs: CO, FORM E, CE/PED (*on demand) |

| Q7: What is your defective goods policy? | Claim window: 7 calendar days post-delivery. Process: ① Joint video audit within 24hrs; ② Identify the cause of the problem; ③ Compensation for proven non-conformance |