Video of galvanized steel tube

Specs of galvanized steel tube

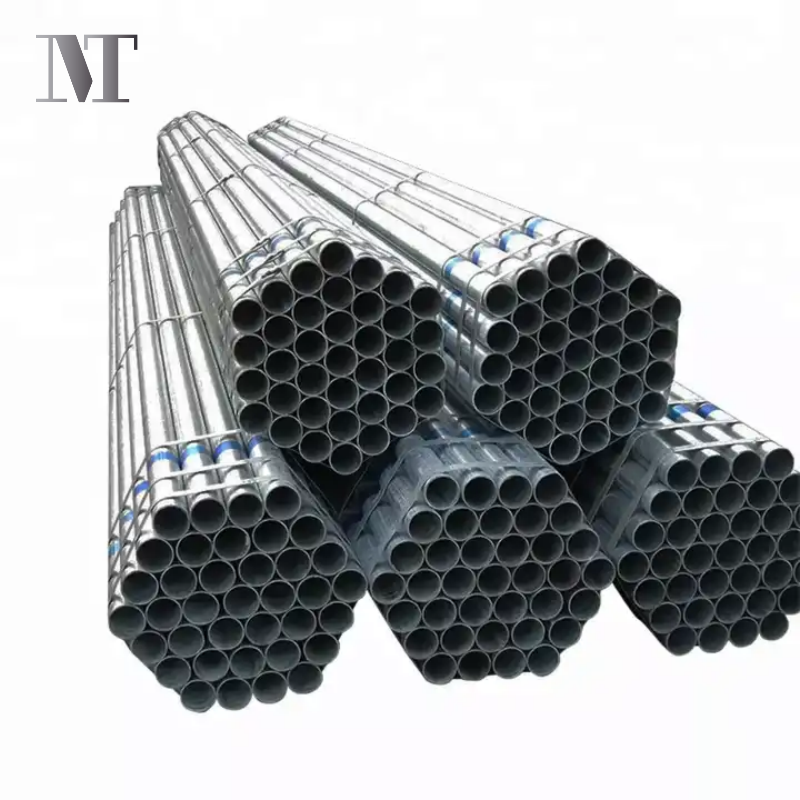

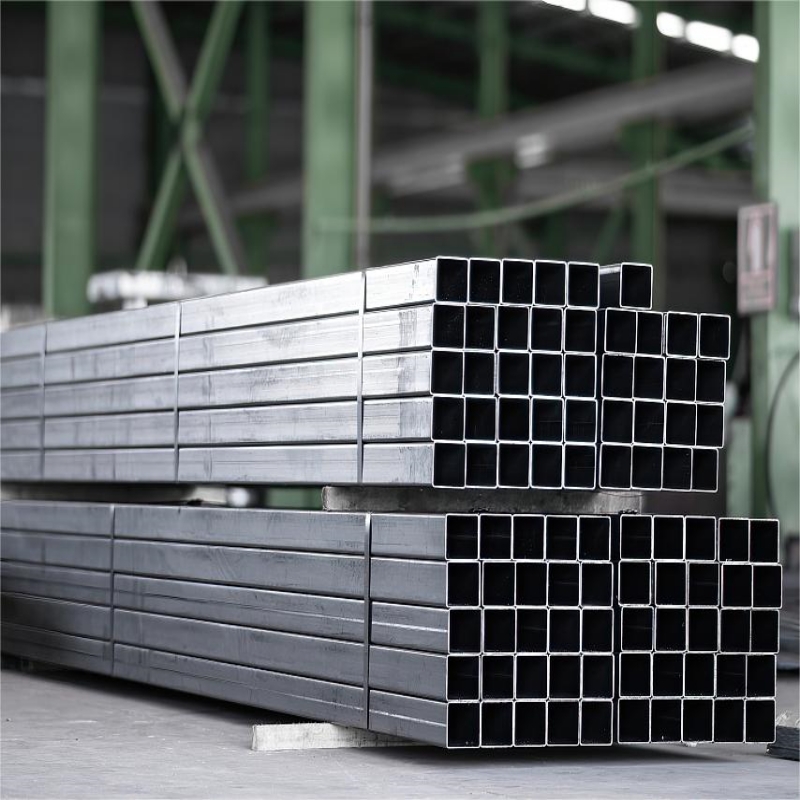

Products Description

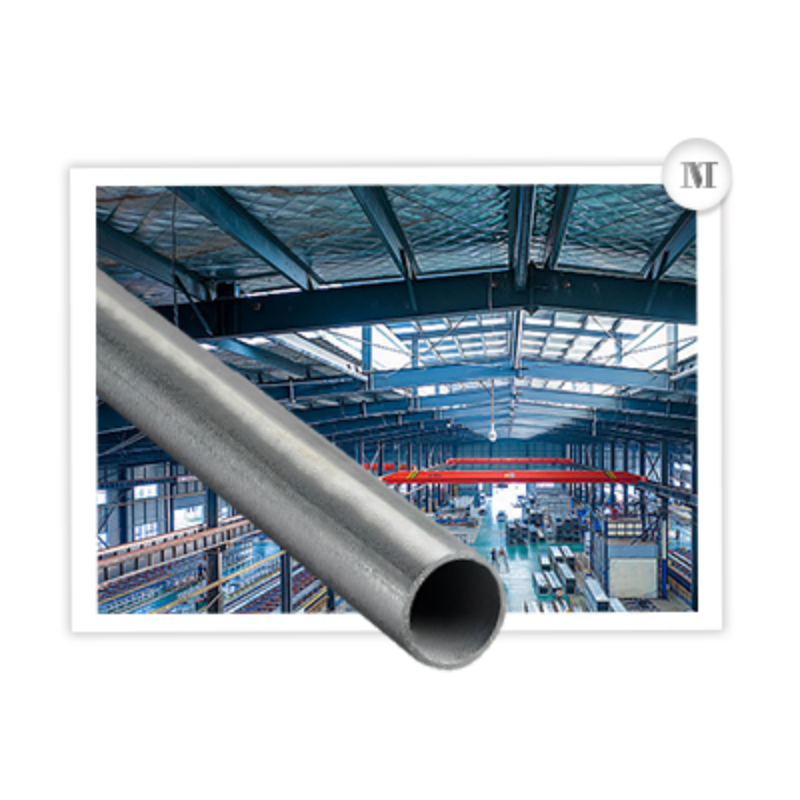

Galvanized steel tubes are carbon steel pipes protected by a zinc coating. This coating acts as a protective barrier between the steel and the environment, providing exceptional resistance to rust and corrosion while significantly enhancing the tube’s overall durability and service life.

Production Process

The manufacturing process of galvanized steel pipe involves a series of steps to ensure the final product is durable and reliable. Below is a brief overview of the production process.

- Cleaning:The steel pipe undergoes thorough cleaning to remove all impurities and contaminants, ensuring proper adhesion of the zinc coating.

- Pickling:The pipe is then immersed in an acidic solution to eliminate surface scale and oxides.

- Galvanizing:After cleaning and pickling, the pipe is submerged in a bath of molten zinc. Through a metallurgical reaction known as hot-dip galvanizing, the zinc forms a tightly bonded coating on the steel surface. Note: Electro-galvanized and pre-galvanized pipes undergo different production processes as previously described.

- Cooling & Inspection:Following galvanizing, the pipe is cooled and undergoes rigorous quality inspection. This step verifies coating uniformity and identifies any potential defects.

- Drying & Storage:Critical Note: Galvanized pipes are susceptible to damage in enclosed, humid environments. Therefore, after manufacturing, they must be stored in well-ventilated, dry conditions.

Buyer‘s Key Considerations

When preparing to purchase galvanized steel pipes, providing detailed information is essential to ensure you receive the product that truly meets your needs. Here are key factors to consider when specifying your order:

- Size:Galvanized pipes are commonly supplied in metric dimensions. However, if your region uses imperial units or gauge systems, don’t worry—Tometal can seamlessly handle the conversions for you.

- Length:Standard lengths include 6m and 11.8m, which are optimized for standard shipping containers(20GP or 40HQ). Should you require custom lengths such as 6.4 or 7.3 m, we can tailor the pipes to your specifications. Be sure to account for transport and installation requirements when determining length.

- Coating:The zinc coating is the most critical factor affecting both the service life and cost of galvanized pipes. A heavier zinc coating extends the pipe’s lifespan but comes at a higher initial cost. That said, investing more upfront can lead to significant long-term savings—Hot-dip galvanized pipes can have a service life up to 20 times longer than electro-galvanized pipes!

- Standards & Specifications:Define the relevant industry standards and technical specifications your pipes must meet. These often include standards set by organizations such as ASTM International or ANSI. For instance, ASTM A500 Gr B can be substituted for other carbon steel pipes due to comparable mechanical properties, while ASTM A500 Grade C—with higher yield and tensile strength—is recommended for more demanding applications.

- Quantity:Clearly indicate the quantity of galvanized pipes you need. Common sizes are often available from stock, but specialized dimensions may require verification against our Minimum Order Quantity (MOQ). Your total quantity will influence delivery timelines and shipping methods—and as in any industry, larger volumes mean better pricing!

- Intended Use:Let us know how you plan to use the pipes—whether for resale, internal projects, or as components in your own products. Our engineering team will be glad to provide expert recommendations tailored to your application.

By clearly communicating your requirements for size, length, coating, standards, quantity, and intended use, you can confidently specify and acquire the galvanized steel pipes that are the right fit for your project.

Tip:When buyers demonstrate strong industry knowledge, they are less likely to be misled by unreliable suppliers.

| Item | Galvanized steel Pipes, Galvanized round pipes, Galvanized Square Pipes |

| OD | 20~405mm in theory |

| Thickness | 1.2~15.7mm |

| Length | Any Length Below 16 Meter |

| Standard | GB,ASTM,BS,EN,JIS |

| Material | Chinese Grade, Q195, Q215 Q235, Q345 |

| ASTM, Grade B,Grade C,Grade D,Grade 50 | |

| EN, S185,S235JR,S235JO,E335,S355JR,S355J2 | |

| JIS, SS330,SS400,SPFC590 | |

| Application | Used For Water, Gas, Stream, Combustible Fluids And Other Liquid Delivery |

| Ends | Plain, Beveled, Thread With Couplings Or Sockets;Plastic Caps And Steel Rings Can Be Provided If Possible |

| Surface | Bared, Galvanized, Oiled, Color Paint, 3PE; Or Other Anti-corrosive Treatment |

| Technique | Hot Rolled Or Cold Rolled ERW |

| Package | Covered With Tarpaulin, Containers Or In Bulk |

| Payment Terms | TT30% Deposit, balance payment before loading |

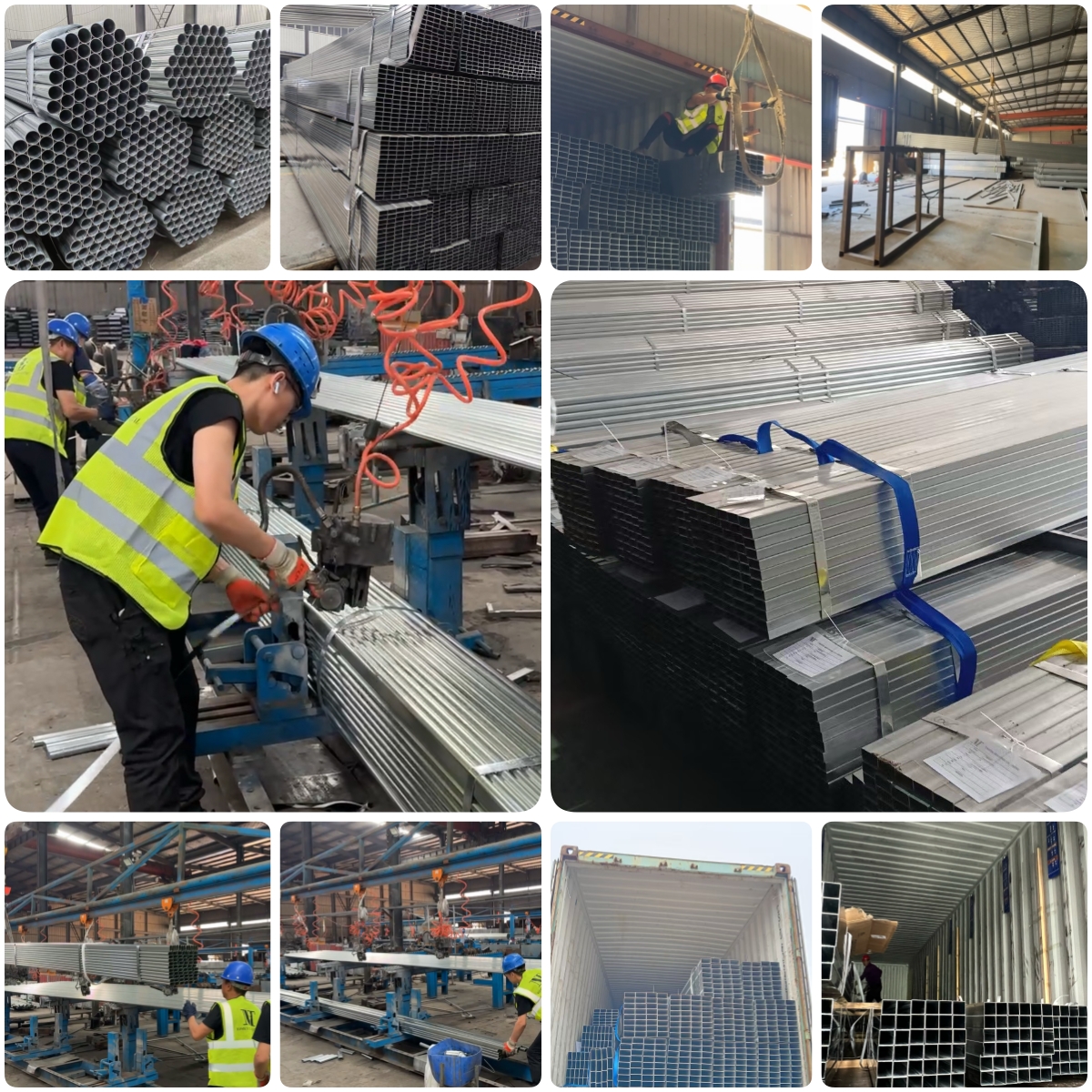

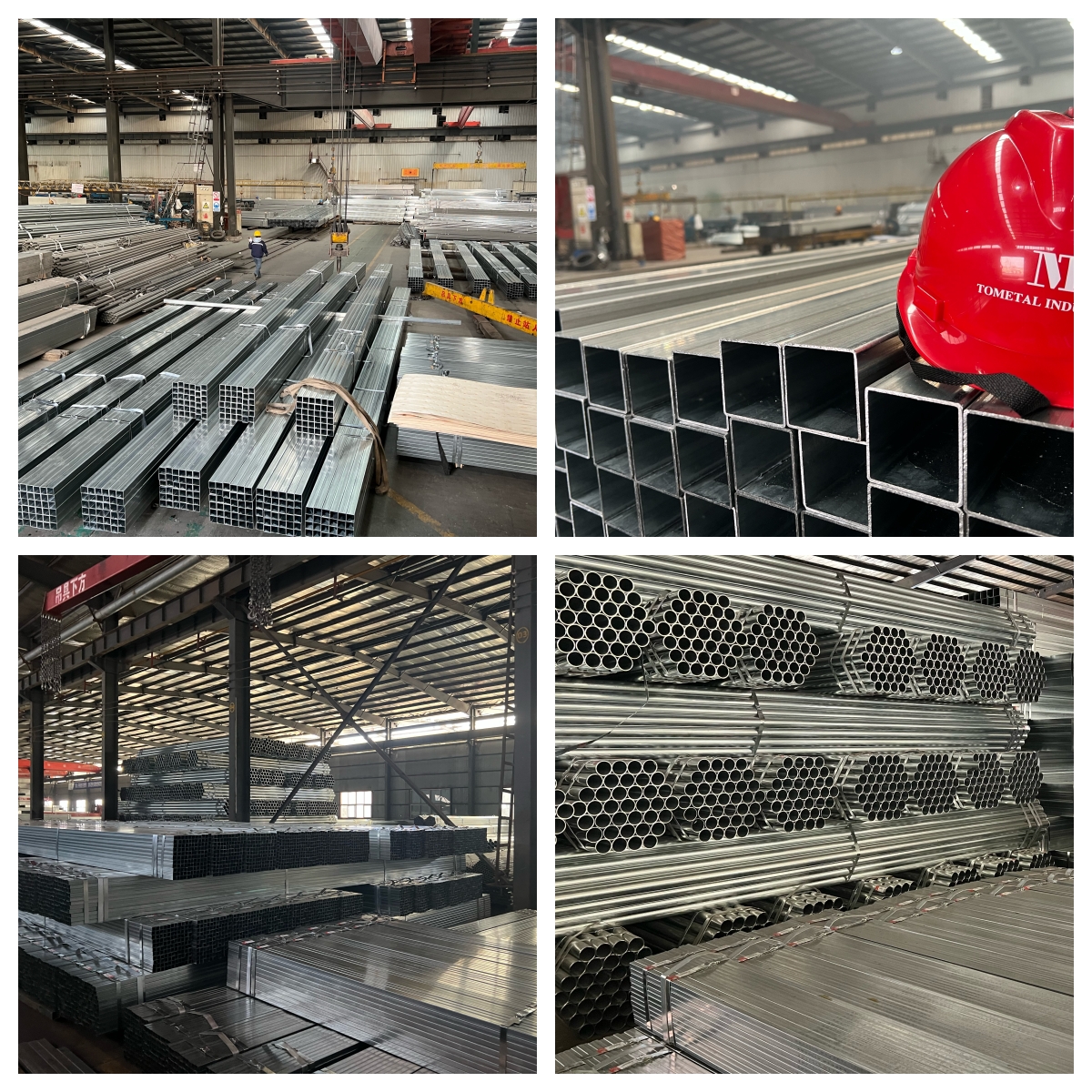

Tometal’s galvanized steel tube warehouse

Product Details of galvanized steel tube

Advantages of Galvanized Steel Tube

Galvanized steel tubes offer numerous benefits compared to ordinary steel tubes, as outlined below:

- Corrosion Resistance:The primary advantage of galvanized steel tubes is their exceptional corrosion resistance. The zinc coating acts as a physical barrier, shielding the steel substrate from moisture and oxygen in the air. Even if the coating is scratched, the zinc provides sacrificial protection by corroding preferentially to protect the underlying base material.

While ordinary steel tubes quickly rust in humid environments, galvanized steel tubes can last several times longer—even decades. - Long Service Life:Thanks to their superior corrosion resistance, galvanized steel tubes exhibit a significantly longer lifespan than ordinary steel tubes. As a result, they are widely used in metal buildings, structural frameworks, critical infrastructure, and other applications requiring long-term stability.

- Low Maintenance:The zinc coating offers a self-healing property, ensuring that minor scratches or impact damage during use do not compromise performance. In cases where the zinc layer is severely damaged, localized re-galvanizing is sufficient for repair, resulting in very low maintenance costs.

- Cost Efficiency:Although the initial cost of galvanized steel tubes may be higher than that of other materials, their extended service life and minimal maintenance requirements lead to substantial savings in upkeep, replacement, and labor expenses. From a long-term perspective, they often prove more economical.

- Versatility:Galvanized steel tubes are suitable for a wide range of applications, including water supply lines, drainage systems, gas conduits, outdoor structures, fencing, and metal buildings. They can also be processed through welding, drilling, bending, and other methods, offering considerable flexibility in use.

Applications of Galvanized Steel Tube

- Water Supply Systems: they are widely used for water distribution systems, both in residential and commercial buildings.It should be noted, however, that some countries have begun restricting this use in favor of more stable and safer alternatives such as copper or stainless steel tubes.

- Gas and Oil Industry: They are commonly used in the gas and oil industry for the transportation of natural gas, petroleum, and other fluids.

- Construction and Structural Applications: With their proven corrosion resistance and high flexibility in fabrication, they are widely used in construction projects for structural purposes. They are employed in the construction of bridges, metal buildings, carports, scaffolding, and other infrastructure.

- Agricultural Sector: They find extensive use in the agricultural sector for irrigation systems, water supply, and the construction of greenhouses and agricultural structures.

- Electrical Conduits: They are also used as electrical conduits to protect electrical wiring in residential, commercial, and industrial buildings.

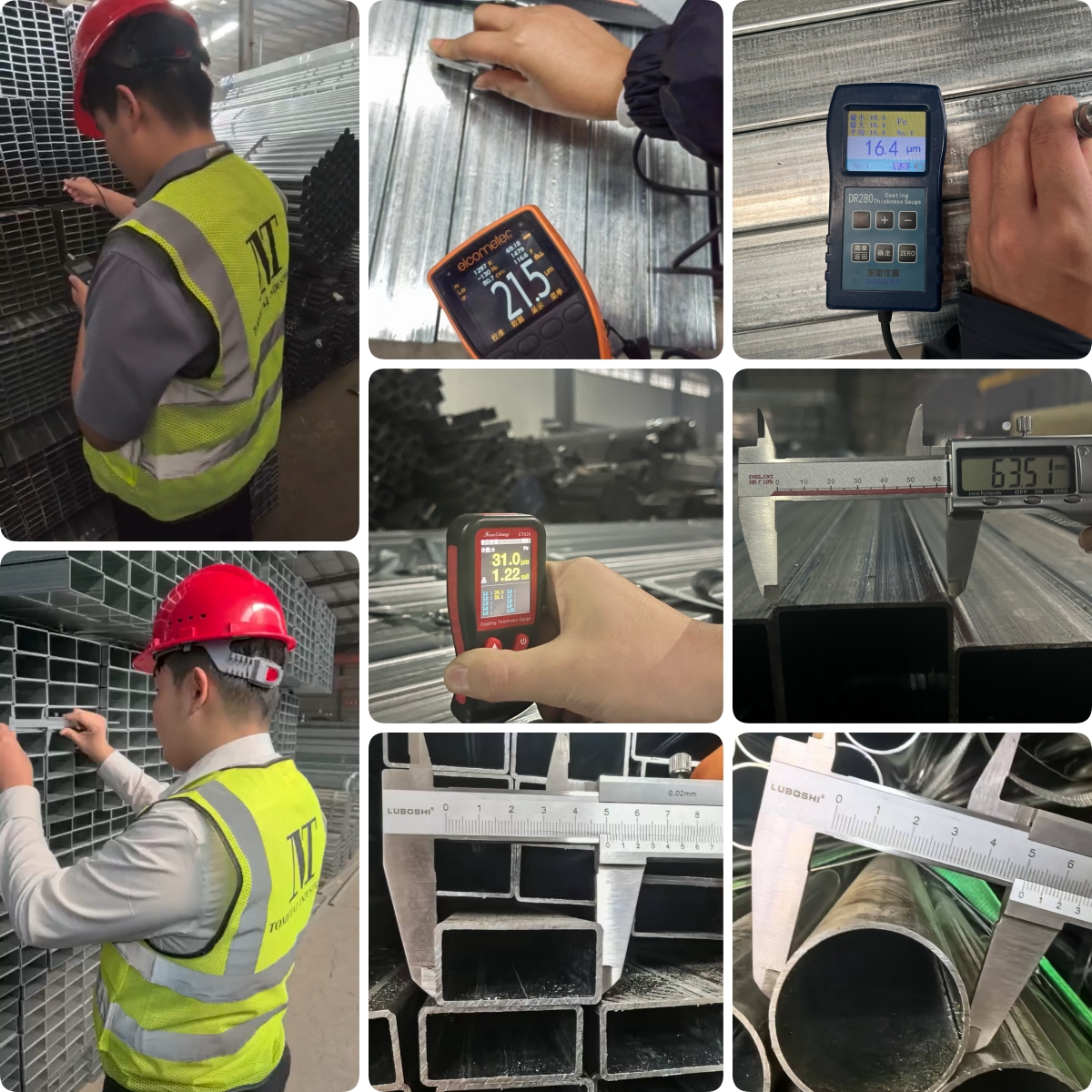

Tometal’s galvanized steel tubetesting

Packaging

Packaging & Shipping

Packaging and shipping are critical steps that determine your final satisfaction with the products received. Before your order departs, please note the following key points:

- Ensure Dry Conditions:Before loading into containers, it is essential to confirm that both your galvanized tubes and the container interior are completely dry. An enclosed, humid environment can easily damage the zinc coating. At Tometal, we store all galvanized tubes for a minimum of 3 days after production in dry conditions to guarantee product quality.

- Minimalist Packaging:Overly complex packaging is unnecessary and may create unintended issues—such as trapping moisture or complicating loading/unloading. Tometal provides optimally designed packaging that ensures adequate protection without excess.

- Select the Right Container:We commonly use 20GP or 40HQ containers for shipments. If you wish to reduce costs, nesting tubes is an available option—but please be mindful of local weight restrictions that may apply.

- Safe Loading & Unloading:Safety is the foundation of all operations. Once your goods arrive, please follow safe offloading practices to prevent potential injury or product damage. With extensive experience in handling galvanized steel tubes, Tometal can provide proven offloading protocols upon request—feel free to reach out!

FAQs:

| Q1: What is the MOQ for galvanized steel tube? | Hot-dip galvanizing: 25 tons Electro-galvanizing and pre-galvanizing: 12 tons |

| Q2: What is your payment term? | We operate on T/T (Telegraphic Transfer) first. Deposit & balance ratio: Flexible negotiation (typically 30% deposit, 70% before shipment). Full SWIFT/BIC codes and proforma invoice (PI) provided within 24hrs post-order confirmation. |

| Q3: How is quality compliance guaranteed? | Our 4-Stage Verification System: ① Mill Test Certificates (MTC) with traceable batch numbers; ② Dimensional/spectral analysis in ISO 9001 & university-partnered labs; ③ Optional third-party inspections (SGS/BV at cost); ④ Real-time production inspection records (photos/videos shared pre-shipment). |

| Q4: What are your production lead times? | Standard stock: 7 working days after deposit clearance. Custom processing: 15-25 days (Technical review within 48hrs). |

| Q5: What custom processing capabilities do you offer? | Key services at Wuxi & Wuhan Centers: Cutting: Laser (±0.2mm), Waterjet, Slitting Surfacing: Passivation, Electropolishing, Anodizing CNC Machining: ±0.05mm tolerance, 0.1° angular accuracy MOQ: 2MT for custom orders; DFM analysis provided. |

| Q6: How do you manage global logistics? | Trade Terms: EXW, FOB, CIF, DAP, DDP Key Routes: Asia/Oceania: 7-12 days via Shanghai/Shenzhen ports Europe/N.America: 20-35 days Export docs: CO, FORM E, CE/PED (*on demand) |

| Q7: What is your defective goods policy? | Claim window: 7 calendar days post-delivery. Process: ① Joint video audit within 24hrs; ② Identify the cause of the problem; ③ Compensation for proven non-conformance |