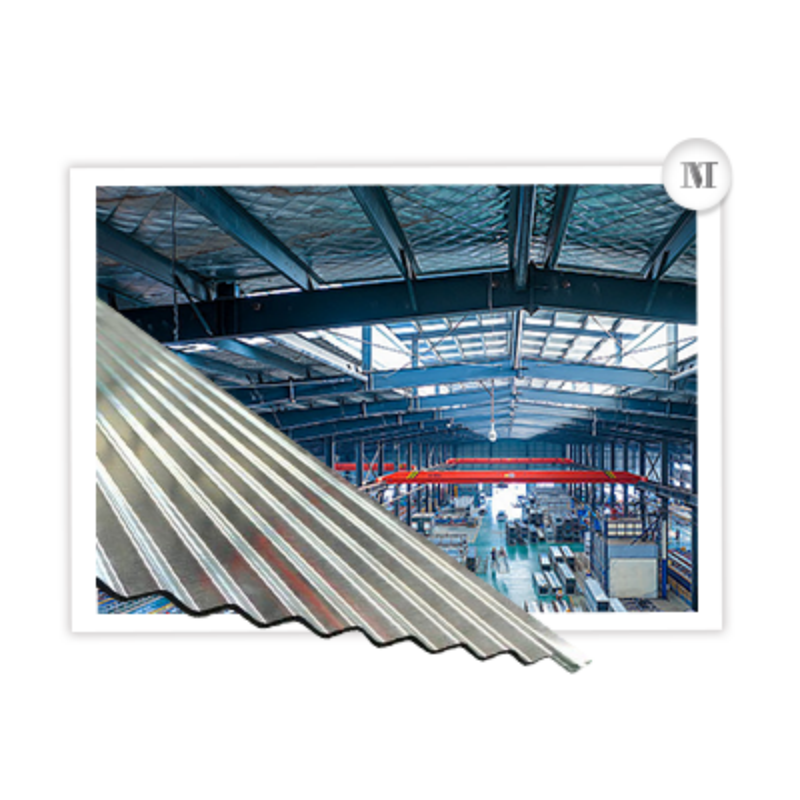

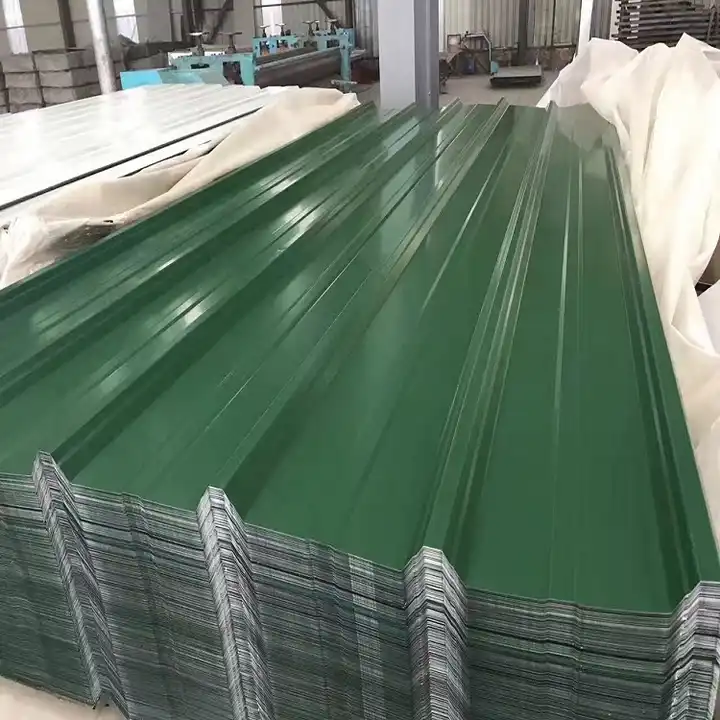

Video of roofing panel

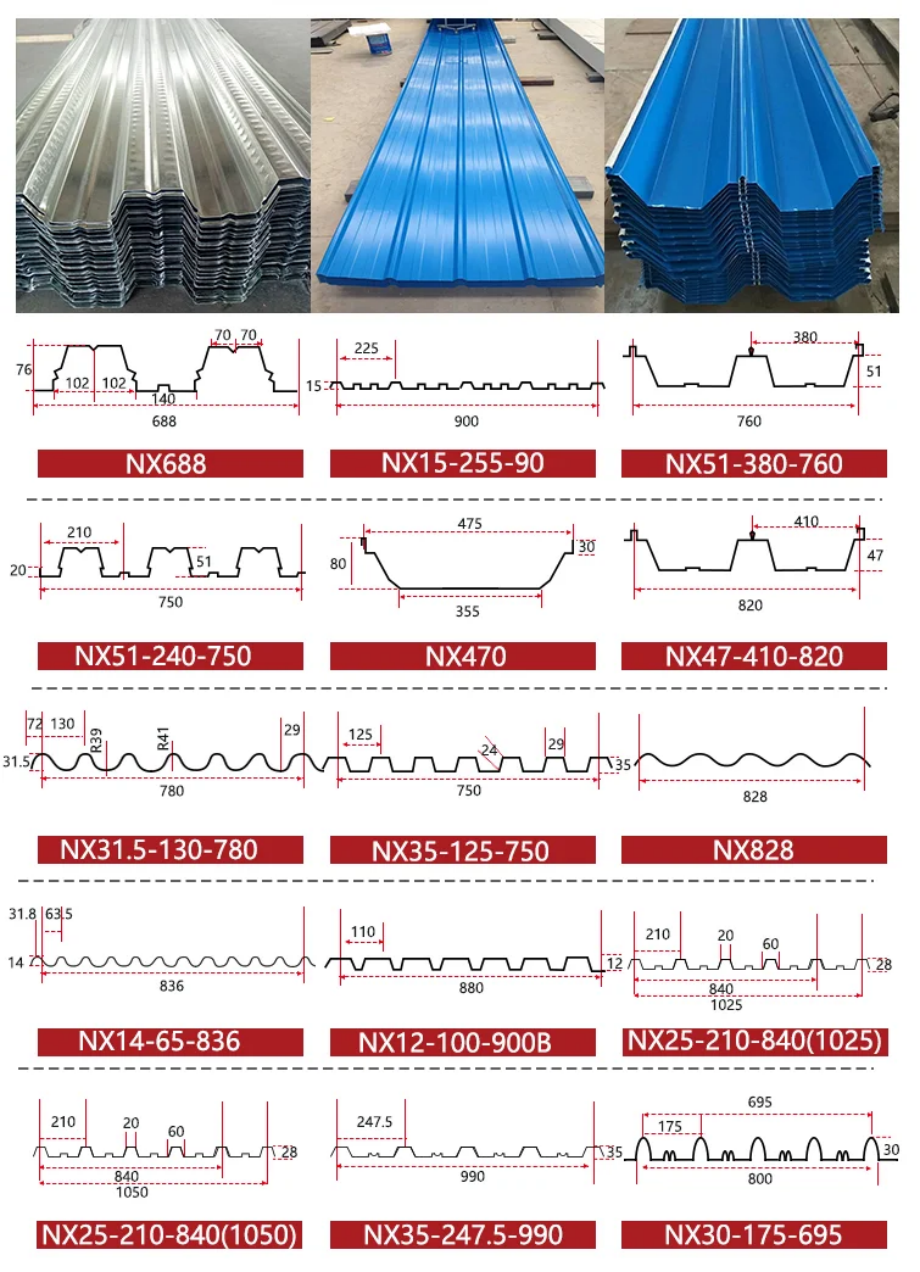

Specs of roofing panel

Products Description

| Size | Thickness <0.6mm |

| Width: 20-1250mm | |

| Standard | JISG3302/G3312;ASTMA653;EN10142 etc |

| Material | SGCC/SGCH/CS Type A and B/DX51D/DX52D/G550/S280/S350 EtC |

| Base metal | Galvanized steel coil or Aluzinc steel coil |

| Zinc/AZ coating | Z:30-275g/m2 AZ: 30-180g/m2 |

| Coll ID | 508/610 |

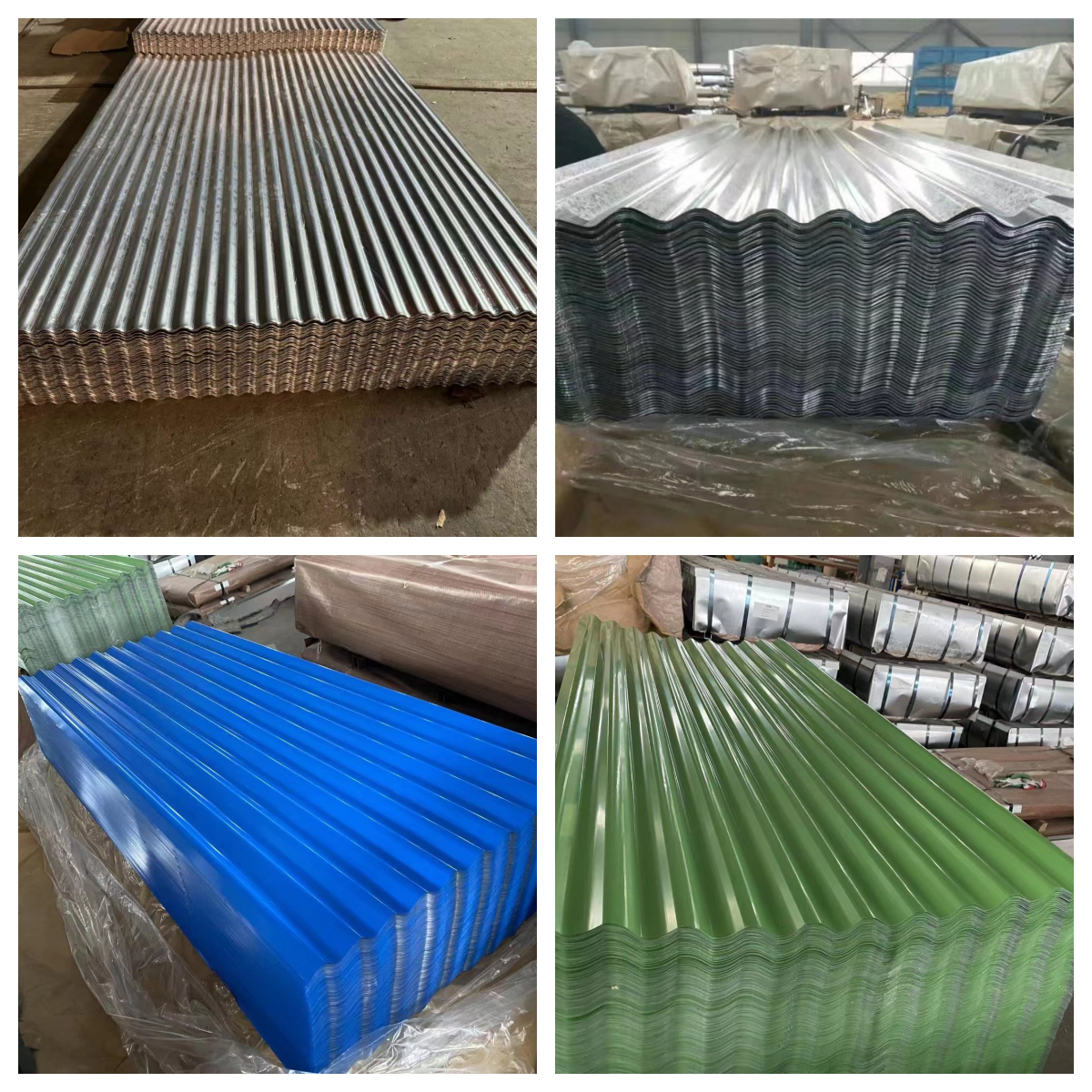

| Color | Ral color |

| Paint | PE/HDP/SMP PVDF |

| Coating structure | Top+Prime 15-25um Back: 5-12um |

| Quality | CQ/LFQ/DQ/SQ |

| Package | Standard exporting package or as your requirement |

| MOQ | 25-27 Ton full one container |

| Delivery time | 15-20days after received deposit according to the quantity |

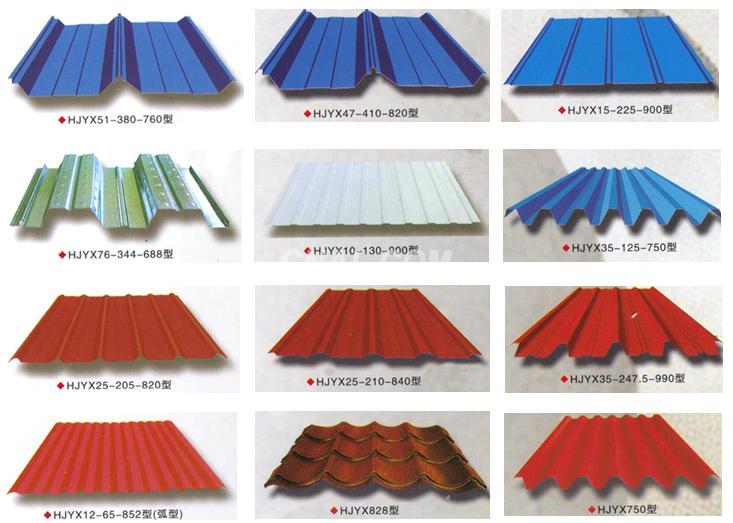

Product Details of roofing panel

Coating Type

Polyester (PE): Good adhesion, rich colors, wide range in formability and outdoor durability, medium chemical resistance, and low cost.

Silicon modified polyester(SMP): Good abrasion resistance and heat resistance, as well as good external durability andchalking resistance, gloss retention, general flexibility, and medium cost.

High Durability Polyester(HDP): Excellent color retention and anti-ultraviolet performance, excellent outdoor durability and anti-pulverization, good paint film adhesion, rich color, excellent cost performance.

Polyvinylidene Fluoride(PVDF): Excellent color retention and UV resistance, excellent outdoor durability and chalking resistance, excellent solvent resistance, good moldability, stain resistance, limited color, and highcost.

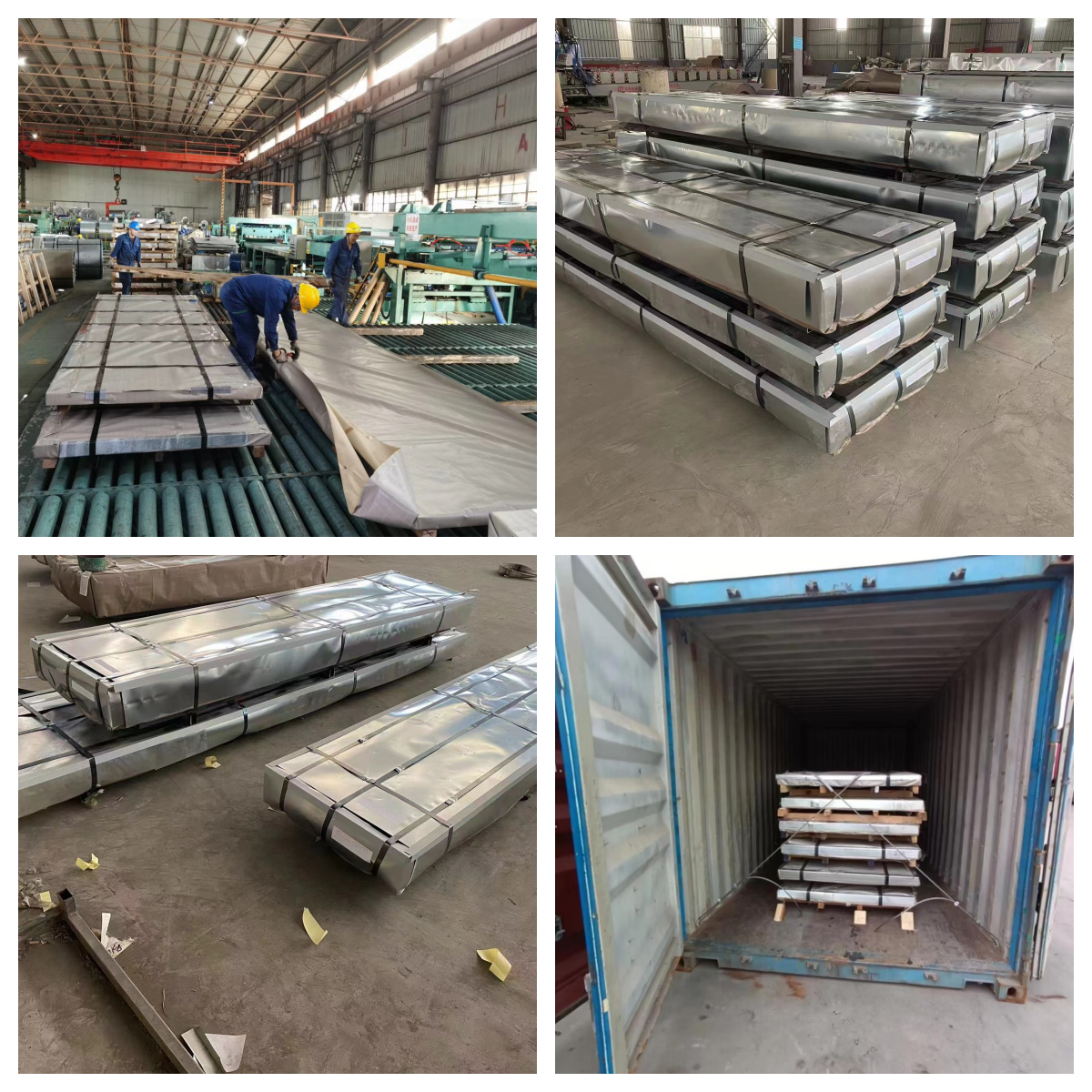

Packaging

FAQ

| Q1: What is the MOQ for Roofing sheet? | 4 tons for each size/color |

| Q2: What is your payment term? | We operate on T/T (Telegraphic Transfer) first. Deposit & balance ratio: Flexible negotiation (typically 30% deposit, 70% before shipment). Full SWIFT/BIC codes and proforma invoice (PI) provided within 24hrs post-order confirmation. |

| Q3: How is quality compliance guaranteed? | Our 4-Stage Verification System: ① Mill Test Certificates (MTC) with traceable batch numbers; ② Dimensional/spectral analysis in ISO 9001 & university-partnered labs; ③ Optional third-party inspections (SGS/BV at cost); ④ Real-time production inspection records (photos/videos shared pre-shipment). |

| Q4: What are your production lead times? | Standard stock: 7 working days after deposit clearance. Custom processing: 15-25 days (Technical review within 48hrs). |

| Q5: What custom processing capabilities do you offer? | Key services at Wuxi & Wuhan Centers: Cutting: Laser (±0.2mm), Waterjet, Slitting Surfacing: Passivation, Electropolishing, Anodizing CNC Machining: ±0.05mm tolerance, 0.1° angular accuracy MOQ: 2MT for custom orders; DFM analysis provided. |

| Q6: How do you manage global logistics? | Trade Terms: EXW, FOB, CIF, DAP, DDP Key Routes: Asia/Oceania: 7-12 days via Shanghai/Shenzhen ports Europe/N.America: 20-35 days Export docs: CO, FORM E, CE/PED (*on demand) |

| Q7: What is your defective goods policy? | Claim window: 7 calendar days post-delivery. Process: ① Joint video audit within 24hrs; ② Identify the cause of the problem; ③ Compensation for proven non-conformance |