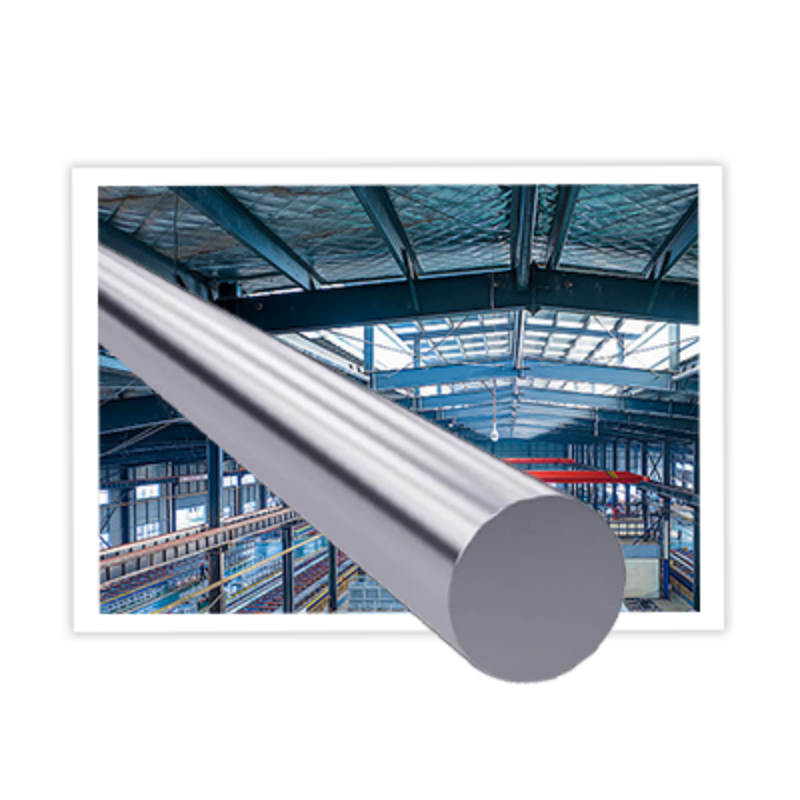

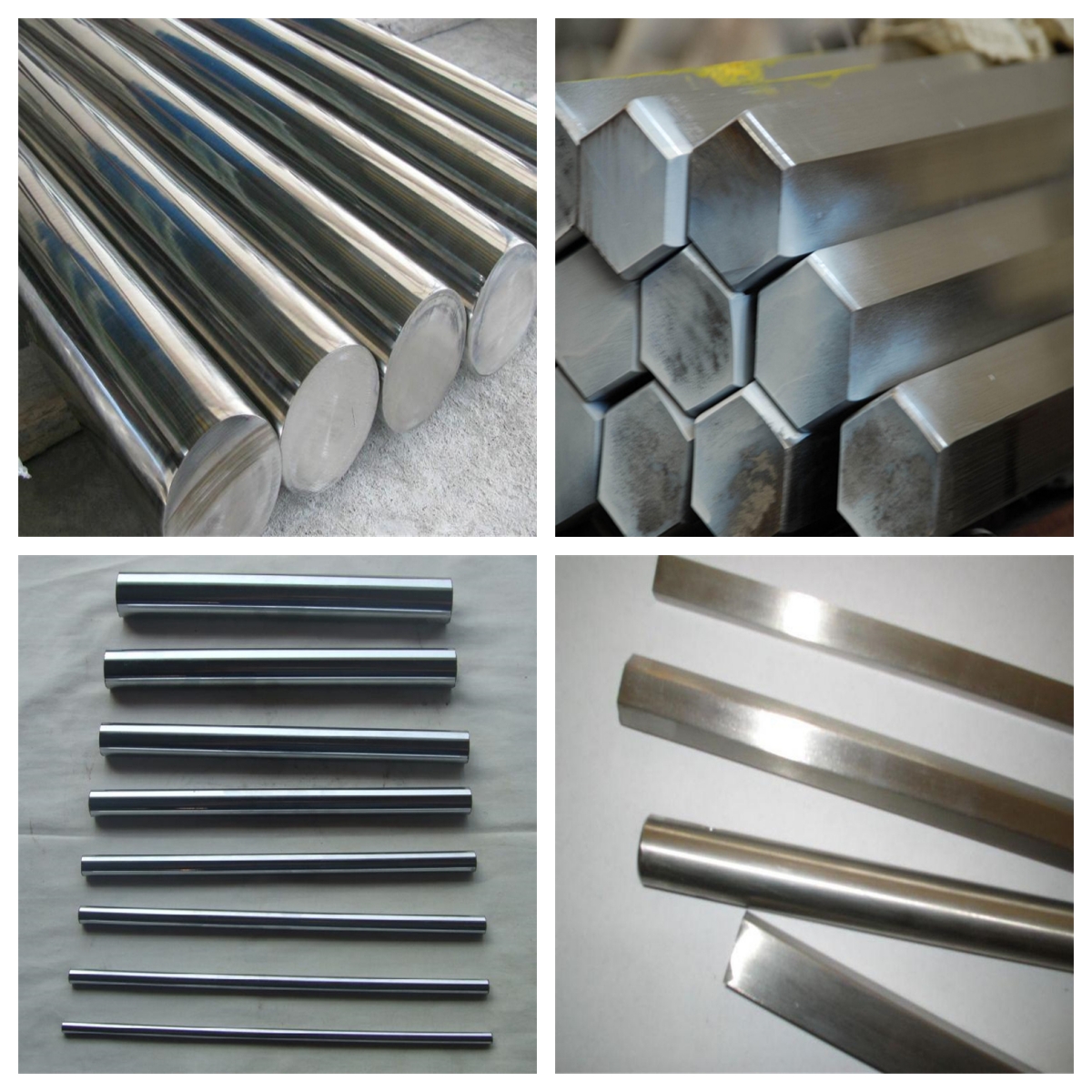

Specs of Stainless steel rod

Stainless steel Bar is widely known as one of the most versatile materials due to its corrosion resistance, strength and hygienic properties, used in everything from construction to the food industry to small appliances.

| Products | Stainless Steel Rod Bar |

| Normal Grade | 201/202/301/302/304/304L/310S/309S/316/316L/321/304J1/410S/420/430 |

| Technique | Cold Rolled; Hot Rolled |

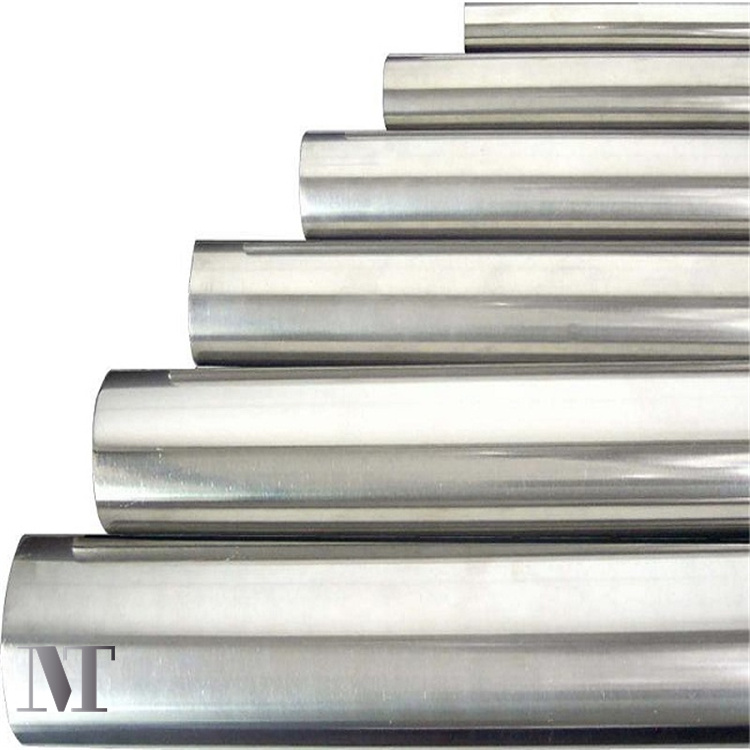

| Shape | Round, Square, Hexagonal |

| Surface | BA, 2B, 2D, 4K, 6K, 8K, NO.4, HL, SB, Embossed |

| Diameter | 3-480mm or as customer’s requirement |

| Length | 3000mm,4000mm,5800mm,6000mm,12000mm or as customer’s requirement |

| Standards | AISI ASTM JIS SUS and GB |

| Applications | Widely used in petroleum,foodstuff,chemical industry,construction, |

| electric power,nuclear,energy,machinery,biotechnology,paper making,shipbuilding,boiler fields. | |

| MOQ | 1 ton |

Product Details of Stainless steel rod

PRODUCT ADVANTAGES

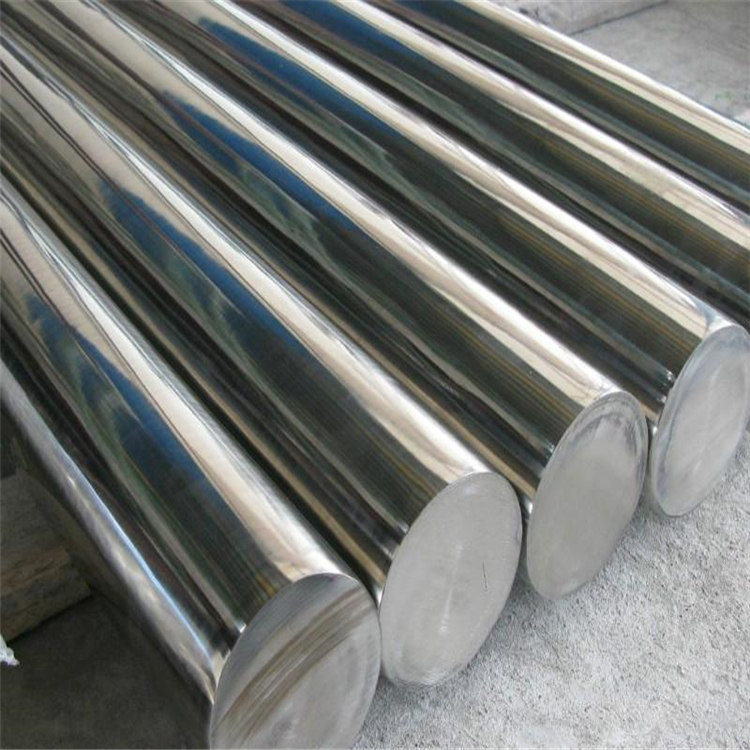

1. Selected materials carefully: high strength, good pressure bearing, firm and pressure resistance, smooth and beautiful inside and outside, not easy to be deformed by force

2. The cut surface is smooth: no burrs, no hand cutting, equipped with good equipment and craftsmanship and a skilled technical team

3. Complete specifications: sufficient inventory, non-standard products support cutting and customization, and provide cutting, drilling, surface and other processing technologies

4. Quality Assurance: Strict quality inspection at outgoing warehouse, only qualified inspection can leave the factory

5. Wide range of applications: industrial industry, automobile industry, machinery manufacturing, construction engineering, ship construction, aviation manufacturing, etc.

2. The cut surface is smooth: no burrs, no hand cutting, equipped with good equipment and craftsmanship and a skilled technical team

3. Complete specifications: sufficient inventory, non-standard products support cutting and customization, and provide cutting, drilling, surface and other processing technologies

4. Quality Assurance: Strict quality inspection at outgoing warehouse, only qualified inspection can leave the factory

5. Wide range of applications: industrial industry, automobile industry, machinery manufacturing, construction engineering, ship construction, aviation manufacturing, etc.

Packaging

FAQ

| Q1: What is the MOQ for stainless steel rod? | 1 tons for each size |

| Q2: What is your payment term? | We operate on T/T (Telegraphic Transfer) first. Deposit & balance ratio: Flexible negotiation (typically 30% deposit, 70% before shipment). Full SWIFT/BIC codes and proforma invoice (PI) provided within 24hrs post-order confirmation. |

| Q3: How is quality compliance guaranteed? | Our 4-Stage Verification System: ① Mill Test Certificates (MTC) with traceable batch numbers; ② Dimensional/spectral analysis in ISO 9001 & university-partnered labs; ③ Optional third-party inspections (SGS/BV at cost); ④ Real-time production inspection records (photos/videos shared pre-shipment). |

| Q4: What are your production lead times? | Standard stock: 7 working days after deposit clearance. Custom processing: 15-25 days (Technical review within 48hrs). |

| Q5: What custom processing capabilities do you offer? | Key services at Wuxi & Wuhan Centers: Cutting: Laser (±0.2mm), Waterjet, Slitting Surfacing: Passivation, Electropolishing, Anodizing CNC Machining: ±0.05mm tolerance, 0.1° angular accuracy MOQ: 2MT for custom orders; DFM analysis provided. |

| Q6: How do you manage global logistics? | Trade Terms: EXW, FOB, CIF, DAP, DDP Key Routes: Asia/Oceania: 7-12 days via Shanghai/Shenzhen ports Europe/N.America: 20-35 days Export docs: CO, FORM E, CE/PED (*on demand) |

| Q7: What is your defective goods policy? | Claim window: 7 calendar days post-delivery. Process: ① Joint video audit within 24hrs; ② Identify the cause of the problem; ③ Compensation for proven non-conformance |