Video of Stainless Steel Coil

Specs of Stainless Steel Coil

| Item | Stainless steel coil |

| Place of Origin | China |

| Brand Name | Tisco/Qingshan |

| Thickness | 0.12 mm-20 mm |

| Width | 5.8m, 6m, 11.8m, 12m or according to customer’s requirements |

| Technique | Cold Rolled,Hot Rolled,etc. |

| Grade | 201, 304, 316, 316L, 430 etc., |

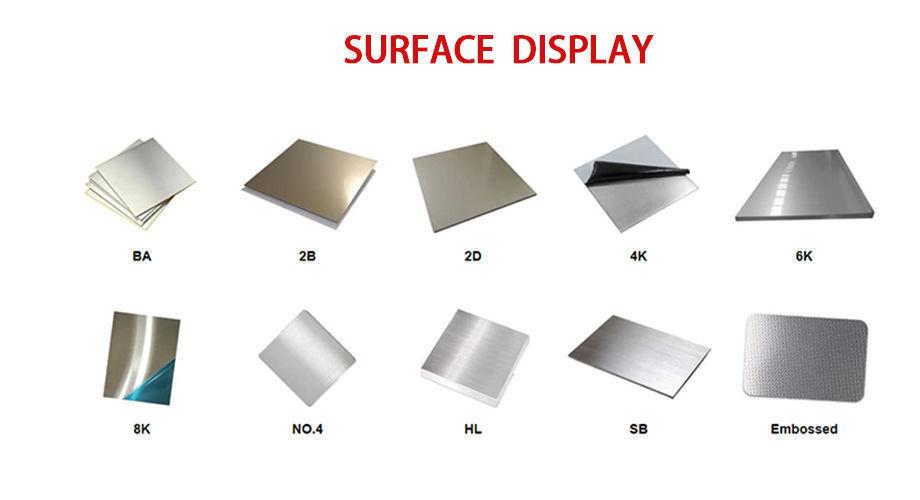

| Surface Treatment | No.4.8K, 8K Mirror Polished, BA/2B/No.1/No.4/brushed/mirror, 8K/BA/2B/NO.1/HL/NO4, etc., |

| Tolerance | ±1% |

| Oiled or Non-oiled | according to customer’s requirements |

| Invoicing | by actual weight |

| Delivery Time | within 7 days |

| MOQ | 1 Tons |

| Payment terms | MoneyGram, T/T (30%DEPOSIT), Western Union, D/A, D/P |

| Package | Seaworthy Standard Package |

| Secondary Or Not | Not-secondary |

| Sample | Freely |

| Inspection | Thirdy Inspection Party |

| Advantage | 24 hours service, fast Delivery |

Product Details of Stainless Steel Coil

Stainless steel coil is widely known as one of the most versatile materials due to its corrosion resistance, strength and hygienic properties, used in everything from construction to the food industry to small appliances.

1)Corrosion Resistance

Stainless steel metal coils has the properties of corrosistance, rust resistance and rain resistance

2)Aesthetic appearance

The bright,easily maintained surface of stainless steel provides a modern and attractive appearance.

3)Ease of fabrication

Stainless steel coil can be cut,welded,

formed,machined,and fabricated as readily as traditional steels.

4)Long Service time

It can endure weight, hot and cold temperatures as well ad weather extremes. No easy to rust and deform

Application

1: Chemical industry: Equipment, industrial tanks and etc.

2: Medical instruments: Surgical instruments, surgical implants and etc.

3: Architectural purpose: Cladding, handrails, elevator, escalators,door and window fittings, street furniture, structural

sections, enforcement bar, lighting columns, lintels, masonry supports, interior exterior decoration for building, milk or food processing facilities and etc.

4: Transportation: Exhaust system, car trim/grilles, road tankers, ship containers,refuse vehicles and etc.

5: Kitchen Ware: Tableware, kitchen utensil, kitchen ware, kitchen wall, food trucks, freezers and etc.

6: Oil and Gas: Platform accommodation, cable trays, sub-sea pipelines and etc.

7: Food and Drink: Catering equipment, brewing, distilling, food processing and etc.

8: Water: Water and sewage treatment, water tubing, hot water tanks and etc.

And other related industry or construction field.

Packaging

| Q1: What is the MOQ for stainless steel coils? | 5 tons for each size |

| Q2: What is your payment term? | We operate on T/T (Telegraphic Transfer) first. Deposit & balance ratio: Flexible negotiation (typically 30% deposit, 70% before shipment). Full SWIFT/BIC codes and proforma invoice (PI) provided within 24hrs post-order confirmation. |

| Q3: How is quality compliance guaranteed? | Our 4-Stage Verification System: ① Mill Test Certificates (MTC) with traceable batch numbers; ② Dimensional/spectral analysis in ISO 9001 & university-partnered labs; ③ Optional third-party inspections (SGS/BV at cost); ④ Real-time production inspection records (photos/videos shared pre-shipment). |

| Q4: What are your production lead times? | Standard stock: 7 working days after deposit clearance. Custom processing: 15-25 days (Technical review within 48hrs). |

| Q5: What custom processing capabilities do you offer? | Key services at Wuxi & Wuhan Centers: Cutting: Laser (±0.2mm), Waterjet, Slitting Surfacing: Passivation, Electropolishing, Anodizing CNC Machining: ±0.05mm tolerance, 0.1° angular accuracy MOQ: 2MT for custom orders; DFM analysis provided. |

| Q6: How do you manage global logistics? | Trade Terms: EXW, FOB, CIF, DAP, DDP Key Routes: Asia/Oceania: 7-12 days via Shanghai/Shenzhen ports Europe/N.America: 20-35 days Export docs: CO, FORM E, CE/PED (*on demand) |

| Q7: What is your defective goods policy? | Claim window: 7 calendar days post-delivery. Process: ① Joint video audit within 24hrs; ② Identify the cause of the problem; ③ Compensation for proven non-conformance |